North Goonyella Mine Fire 5th October 2018. “During the night the Mine had located 38 surface to seam holes and identified 5/6 that were breathing in strongly. These have all been sealed.”

MRE – North Goonyella – 05.10.2018.pdf

Today, 5 Oct 2018 1, Inspector Les Marlborough, accompanied by Inspector of Mines Geoff Nugent attended a meeting at North Goonyella Mine to discuss the status of the spontaneous combustion event at North Goonyella Mine and the subsequent mine evacuation. The meeting was held at the North Goonyella accommodation village in the IMT Room.

Prior to the meeting Mr Anger notified us that, as per the plan, a camera had been lowered down a borehole into MG 9N A Hdg 1-2 CT. The camera had subsequently been lost in the hole due to the support chain breaking.

Mr Baker and Mr Anger gave me a brief summary of recent events while I had been away from the Mine. On 27 Sep, following the sealing of the TG Chute Road smoke started to be seen at the upcast shaft through the main fan. This occurred for approximately 4 hours. There was then a suspected explosion or overpressure event that lifted the explosion doors on the main fan enclosure. At 3:30 AM on the morning the smoke stopped, then started briefly then stopped again. At this time the smoke started to report out of the M&M Drift and the Conveyor Drift and the intake Shaft H9. At the same time, the main upcast shaft reversed airflow and reverted to downcast (intake air). At this time the bleeder shaft was intaking strongly. The GAG was set up on Sat 30 Sep onto the Bleeder shaft and has been running ever since (apart from a maintenance issue). Rocksil plugs have been pumped into the and 1:4 drifts and the main upcast shaft has been sealed with Rocksil Foam.

Meeting

Attending the meeting was;

Mr John Anger, SSE;

Mr Peter Baker, VP Peabody Australia;

Mr Chris Markowski, Tech Services Superintendent;

Mr Gareth Prichard, Planner.

In addition, the meeting was joined by video/telephone conference by;

Mr Nev Impson, Compliance Manager;

Mr Luca Rocchi, CICM; Mr Shaun Dobson, DCICM; Mr David Cliff:

Mr Martin Watkinson (SIMTARS).

Meeting

Last 24 Hours;-

Simtars camera lowered down Hole 2702 (into MG A Hdg 1-2 CT). Photos taken from the camera showed no obvious signs of fire in the area. The photographs showed hoses and plastic fittings which showed no sign of being affected by fire. The photographs showed the roof mesh was partly obscuring the hole,

The camera has a temperature monitor that alarms at 68C. This alarmed after 10 minutes so the camera had to be withdrawn. When trying to recover the camera the support chain snapped and the camera was lost down the borehole. The Mine is going to conduct one attempt to retrieve the camera then ream out the hole through with the drill rods.

The GAG ran for the full 24 hours. There is a requirement to shut the GAG down for 2 hours every 48 hours for maintenance, following the afterburner ring failure from earlier in the week. This will occur on Saturday.

Drilling attempting to complete hole 2701, into MG Chute Road. Hole 2703 (MG 9N 2 CT) is approximately half way.

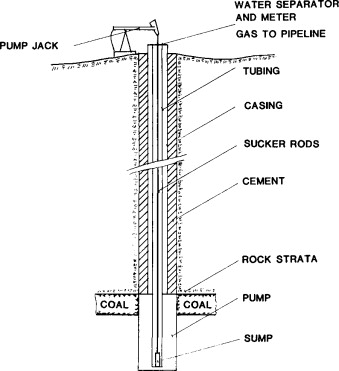

The H40 Shaft had been sealed small areas around the ducting. During the night the Mine had located 38 surface to seam holes and identified 5/6 that were breathing in strongly. These have all been sealed.

The Mine has reviewed the remote operation of the dozer in case it is needed for emergency sealing and preparations are underway to prepare sealing material should it be required.

Current Status

The gas results from shaft H9 were discussed. It was acknowledged that there was still activity occurring underground, and this was probably a gas fire. There was discussion regarding the results from various locations and it was generally agreed that more detailed analysis was required to make any conclusions.

There was further discussion regarding the air quantity coming out of Shaft H9 and how this could be measured, or estimated. This would give valuable information to help understanding the status of the Mine, There was discussion around possible sources of additional Methane. It was suggested that the gas risers be checked and the flows measured. The Mine explained that the gas risers had been turned off on the surface.

I recommended that the Mine reconsider this with a view to opening up the risers. The hazard being that, by closing the gas risers, the boreholes would pressurise from the underground methane standpipes. This pressurised gas could then cause the underground water traps to blow out. This would result in the in seam gas drainage holes free venting into the underground mine atmosphere. The Mine agreed to review this.

We discussed the ongoing manning requirements for the Mine. Mr Baker explained that 24 of the workforce would be deployed temporarily to another mine in NSW to assist with a

Longwall relocation. He stated that the Mine was assessing the ongoing manning requirements to cover the current situation. The numbers required were quite a lot more than expected, plus ERZ Controllers and other staff.

Next 24 Hours

Work has commenced to set up Floxal units at 6 CT ION Corridor and 9N 1.5 CT B Hdg. This work will continue. These will be run for 24 hours and the situation monitored.

Lighting platforms to be set up near H9 Shaft.

The Mine is looking at locations to drop tube bundle monitoring in the mains so that they can gain an understanding of the atmosphere around the Mine.

The Mine will relocate the Drill Rig from 9N A Hdg to the TG Chute Road to rem out the hole used to insert the Rocksil Plug to test whether the plug is still in place.

Following the meeting, I undertook the new induction for visiting the surface operations at the Mine and conducted an inspection of the surface work areas. I was accompanied by Mr Anger and Mr Marek Romanski, UMM.

Access control to the Mine surface area was well controlled with 2 check points controlling site access. We were issued SCSR to remain on our person at all times.

We visited the GAG operation site. This was well set up and the operators fully understand their role and the hazards and controls with the work they were undertaking. Road conditions up to this site were good and well maintained. An ERL Controller was present at the GAG site, and is present at all times.

We inspected the Portals, as close as the exclusion Zones would allow and the H9 and H40 Shafts, again, as far as the exclusion zones would allow. I commented on the standards of barricading these exclusion zones, which was poor. Mr Anger agreed to have these barricades addressed.

At H9 Shaft, there was no clear evidence of smoke emanating from the shaft and no evidence of a large amount of air from the underground venting from the Mine. We discussed the ways that a measurement of airflow up this shaft could be achieved without exposing anyone to an unacceptable level of risk.

On return to the Accommodation village I informed Mr Romanski that I would return to the Mine at 08:00 AM on Sat 6 October.