North Goonyella Fire MRE 17th September 2018. “If the mine is to plug the TG chute road the impact must be assessed as part of the plan”

MRE – North Goonyella – 17.09.2018.pdf

Today, Monday 17 Sep 2018, at 1pm, Inspectors Les Marlborough, Richard Gouldstone and Geoff Nugent attended a meeting at North Goonyella Mine to discuss the status of the high CO in 9N TG. Inspectors were met by Marek Romanski, UMM.

Meeting

Attending the meeting was;

Mr Marek Romanski – UMM

Mr Peter Baker – Peabody Operations Manager (by telephone connection)

Mr Nev Impson – Compliance Manager

Mr John Pearson – SSHR

Mr Robin Hall – Business Development Manager

Mr Gavin Shields – SHE Manager

Mr Jeff Perks – HST Superintendent (Scribe).

Last 24 Hours;

- Continued monitoring gases and injection of inert gas as per plan o Drilling GN2696 (grout and re-drill until closer to seam target 30-50m) @ 81.35m

Drilling GN2695 (grout and re-drill until closer to seam target 30-50m) @ 244m cased and grouted waiting for grout to cure

- Transferred Floxal #1 feed from GN2690 to GN2693

- Inject UIS CH4 into GN1991 from 6pm started with 600 1/s 05:00 1 10 Ifs (suspect water in line)

- Injected QMRS foam from GN2470 18:40 shut down due to high pressure 23:50,

N2 from Floxal unit #1 only running (No low barometer diurnal last night )

Current Status

o Gas readings for the previous 24 hours were provided and discussed. e Tube 24 Stable and inert;

- Tube 29 showed a slight increase in CO in the TG Chute Road. The CO now, according to the Gas Chromatograph in the TG Chute Road increased to 600PPM, believe to have been affected NGC floxal failed coupling reducing flow to 3331/s

- Tube 28 reflects the results shown in the TG Chute Road. However, there is still a significant difference in CO make when calculated between tube 28 and 29. This indicated there was a significant error in the ventilation quantity being used at one of these points.

- Analysis of gases indicates that there has been a reduction in the ventilation quantity in the TG chute.

Plan for the next 24 Hours

- Establish dewatering on UIS CH4 line

- Mobilising Rig 1218 for TG chute road plug borehole

- When GN2695 is holed we will move the rig to the TG chute road hole if Rig 1218 unavailable (Prep for sealing from surface) Mobilising Wilsons equipment to inject plug in TG chute.

- Mobilising Liquid nitrogen tanker ETA Wed

- If GN2695 holes before liquid N2 arrives hook up floxal #2

- Continue Floxal injection as per current plan (attached);

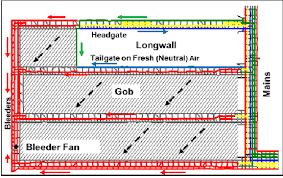

Strategy remains to maximise inert gas flowing into the Goaf area on the MG side of the TG Chute Road.

Inspector Marlborough had yesterday recommended that the Mine needs to take additional time when drilling new holes to ensure that the holes get closer to the coal seam. He explained that there is a possibility that a lot of the inert gas being injected into the new goaf holes is filling cracks and joints. The Mine are attempting to achieve this aim.

Copies of the current gas data spreadsheets, an update summary and a plan showing the injection points being used and the quantities of inert gas being injected were provided.

It was again stressed that if the mine is to plug the TG chute road the impact must be assessed as part of the plan i.e. ensure the change management process is applied via a formal risk management process considering as a minimum, the impact to ventilation, gas monitoring (including the requirement for effective monitoring after the proposed change), the risk the change may cause to explosibility, and the risk to people on the surface conducting operations around boreholes and at portals.

Inspector Marlborough thanked the attendees for their time and explained that Inspectors Gouldstone and Nugent will return tomorrow to review progress and to discuss plans going forward.