Grosvenor Ventilation System LW104. Is it some Unique; Bastardized version of United States Double Entry Retreating with Back Bleeder

Inspector Smith’s testimony during yesterdays Grosvenor hearings he made mention of having C heading in the tailgate open to the goaf via cut-throughs behind the face and having brattice stoppings erected in them.

Inspector Smith then talked about methane exiting the goaf via these cut-throughs travelling outbye down C Hdg then rejoining B heading Tailgate Return outbye the 400m Tailgate Sensor.

He also made mention that he thought that it was “basic mining” to keep these brattice stoppings in good condition.

I admit I was totally confused as to how Grosvenor was ventilating the block.

I have never ever heard of such an arrangement, let alone seen it.

Yesterday and last night I got out some old Mining and Ventilation text books.

After being unable to find anything that seemed relevant I spent an hour or so of searching on the Internet, trying to locate something that sounded like how Grosvenor LW 104 seems to be ventilated

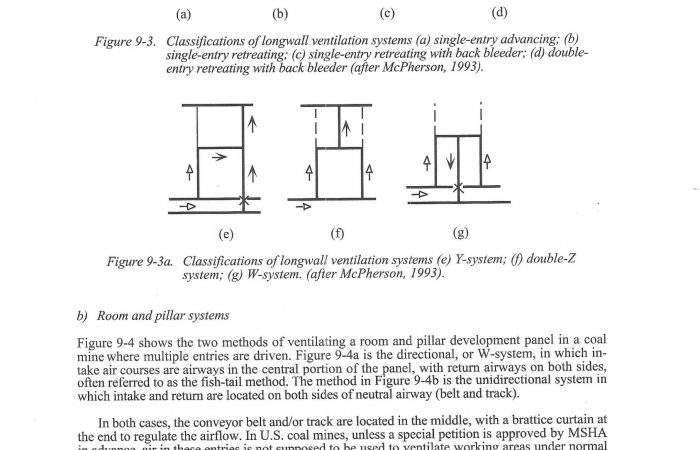

I found this Chapter of what seems to be a USA Reference Book entitled Mine Ventilation Systems. On the 5th page of the Chapter (pg 166) there is a diagram

mcPherson ventilation double return

Even this example seems only used in the USA, is not what Anglo are doing at Grosvenor.

USA Mines from what I am aware of are governed by a completely different philosophy of ventilating longwall goafs and are subject to a completely different set of Mining Rules and Regulations trying to achieve different outcomes.

Also it is widely reported that USA coals are not as prone to Spontaneous Combustion as Australian coals and in particular Queensland Coals.

Also USA mines are in the main 3m in thickness or less

For budding students of Longwall Mining styles employed in the United States this paper may assist.

From what was presented at the Grosvenor Inquiry yesterday this is not what was in place at Grosvenor.

Bleeder Roads in this USA only system are a return airway not an intake airway as Grosvenor 104 seems to be.

The whole concept of the USA system is based on pulling the explosive fringe away from the longwall face and bleeding off excess methane out the back of the longwall panel and then out of the mine via the bleeder shaft and fan.

This is the exact opposite effect of what Grosvenor were doing.

As to

- C heading and open cut-throughs with brattice stoppings behind the Tailgate of the longwall, and

- C heading then acting as a parallel unmonitored roadway that rejoins B heading LW 104 Return outbye the 400m Sensor,

try as I might I just cannot understand the philosophy, ventilation and mining practices behind it.

Maybe a decent Mine Ventilation plan would help.

As to having brattice stoppings as in this arrangement as Rated/Effective Ventilation Control Devices I just cannot fathom.

Just who on earth dreamt this arrangement up?

What is it even called? Does it even have a name?

Was this arrangement discussed in the 2nd Workings Plan submitted to the Inspectors around the 6th of March 2020 just prior to the Longwall starting on the 9th March?

Were the Mines Inspectors of the belief that this ventilation arrangement (it is not a system in my view) achieved “an acceptable level of risk”

If so how for what reason?