North Goonyella Mine Fire 9th October 2018. GAG was experiencing back pressure which was conjectured to be the result of possible roof falls/flooding”

MRE – North Goonyella – 09.10.2018.pdf

Inspector Richard Gouldstone arrived at NGC Mine Camp at 07:15am on Tuesday 9 October 2018 to attend a meeting in regard to progress on dealing with the spontaneous combustion and subsequent underground fire event.

Update Meeting at NGC Camp @ 8:30am.

Present —

Richard Gouldstone (Mines Inspector)

John Anger (SSE)

Marek Romanski (UMM)

Kris Markowski (TS Superintendent)

Gareth Pritchard (Group Planner— Scribe)

John Fitzpatrick (MSO)

Casey Moore (ISHR)

Stephen Woods (SSHR)

Neville Impson (Compliance Manager)

Josh Cook (Graduate Mining Engineer)

By dial in

David Cliff (Consultant)

Darren Brady (Consultant)

Les Marlborough (Mines Inspector)

Mike Carter (Millennium SSE — IMT member)

No major changes in direction in the last 24 hours

Last 24 Hours

- Gag running, but down from 15:15 to 19:20 with a fuel pressure rack issue (motor loose, component tightened), and then for maintenance from 06:45 to 10:30am (continuing at the time of writing but soon to restart). It was experiencing back pressure which was conjectured to be the result of possible roof falls/flooding. 48 hours shutdown planned for 14 October. MG belt road plug in place(Sat pm/Sun am).

- Borehole GN2703 (MG A Hdg 2 CT) — now almost plugged. This leaves only MG chute to plug plus TG which will to add to the incomplete seal already in place. Borehole GN2701 (MG Chute Road) — ready for plugging after MG cut through, estimated completion by midnight today.

- GN2704 (TG Roadway) Down to seam and ready to set up for holing into workings today with the normal precautions, Floxal 4 to assist.

GN2705 — Rig 1226/1265 swapped due to hole design and rig capability now down 100m.

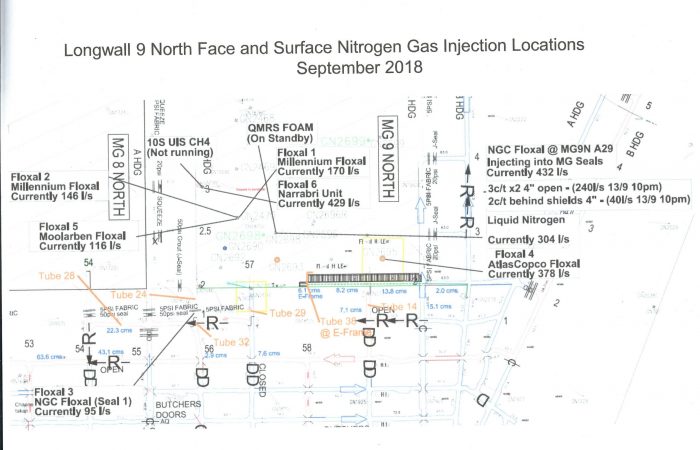

Floxal Unit #6 set up over 42 CT (Stone Dust Silo) @ 7501/s. This running continuously. Floxal Unit #2 at 6 CT in the Corridor, Run all night @ 3201/s. This running continuously.

- Borehole monitoring, 1-19 4hourly, GN2700J 1946, 2695, 2698, 36CtD-E, 25Ct 9N and 44Ct E Hdg (unreliable samples thought to be emulsion product) all at 6 hourly intervals.

- Emergency sealing preparation works continued at H40 & 1 in 4

- H9 temperature at 57/58 degrees C, drone with thermal indicator to be used as a check

UIS flaring 2Ct & 4 Ct MGIO8

Crib and facilities improved for gate crew

Next 24 Hours

Continue GAG operations

GN2703 then GN2701 Rocksil Plug works

Continue drilling for LW containment — concrete seals to compliment the rocsil plugs

Continue Sampling Regime and seek replacement for 44E

Revise Floxal Strategy — no plan to increase inertisation of goaf, NGC unit into 3Ct only

Preparation of sealing strategy

Conducting prep work for Radon heat survey

Gas flare maintenance planned IMT change over Tues to Weds

Discussion

- Latest H9 results showing slight blip in readings — too soon to be indicative o E44 shows fresh air — to be replaced o D. Brady noted a change in results just in from 36Ct, floxal unit to be checked and a re-sample agreed

- Volume at H9 still not known — option suggested to drop ‘foil’ and effect of updraft may give an order of magnitude

- Still accepted that with the uncertainty of the status of VCDs potential impacts of changes will be difficult to predict — plugging of all access to LW9 should prove most informative — subject to the status of the two TG seals/plugs

- Advice was given in regard to alternative analysis device for 95% methane samples

Inspection

Following the meeting Richard Gouldstone, John Anger, Marek Romanski, Casey Moore and Stephen Woods visited the following locations –

GAG site – routine maintenance was nearing completion and it was noticed that the shaft was breathing out.

Portals – debris viewed ready to place if required

H9 – Blackened superstructure clearly in view

H40 – rocsil plug and debris ready to place if required

All operations viewed were adequately supervised and controlled, segregated to prevent inadvertent access to exclusion zones with security checks at appropriate approach positions.