North Goonyella 7Nth Heating MRE 14 January 2014. Similarities between 7 Nth Heating in 2014 and 9 Nth Heating and Fire in 2018

There are a number of close similarities between the 7 Nth heating in January 2014 and the 8 Nth heating, fire and explosion in September 2018.

- Both in final take-off position and Longwall move under way

- Ethylene Detected

- Not easily able to obtain records from previous Spontaneous Combustion events at North Goonyella.

- Water accumulations altering the existing ventilation pressures and circuits.

- Lack of pressure survey data on the goaf.

- Floxal Inertisation being used.

- Inability to remote sample

Inspector Albury was made the following suggestion about being able to use boreholes to remotely monitoring and obtain gas data after the mine has been evacuated.

This would have saved an awful lot of precious time in 2018

I suggested that the mine prepare a process for taking gas bag samples from boreholes and ensure there are boreholes and sites available should the SIMTARS mobile lab be required and the mine is evacuated. This is a precautionary process in the event that an evacuation occurs and gas data from underground has to be gained from the surface.

The big and obvious difference: “Prep Seals” have been constructed in 2014

140114 7N Prep Seals Ethylene Albury DME MRE

A site meeting was conducted today, 14/01/14, at the North Goonyella coal mine by Deputy Chief Inspector Mr Russell Albury and Principle Investigation Officer, Mr Andrew Broadfoot. We arrived at the mine site at 10:40am and were greeted by the UMM Mr Michael Lerch. The mine was in the process of finalising their daily spontaneous combustion review meeting in relation to 7 Nth and the Inspectors were invited to join the meeting.

At the meeting were M. Lerch (UMM), L. Marnane, G. McGetrick, D. Craft, N. McAlary and M. Romanski was participating via speaker phone from Brisbane.

The reason for the visit was to determine the progress of the mine in treating, identifying and planning to manage the elevated CO readings in TG 7 Nth. Discussions were held pertaining to the issue and covered the following points; the mine does not know the cause of the elevated CO readings at this stage.

The Ethylene of 1.7ppm detected in the TG goaf stream appears to be “noise” in the Gas Chromatograph. The mine is not confident in the GC ability to accurately read Ethylene at levels below 5ppm. The mine has sent samples to Moranbah North for verification. The Moranbah North GC detected similar quantities of Ethylene in the sample.

I mentioned that the mine should consult SIMTARS and especially Martin Watkinson for help as I am aware that Moranbah North had trouble last year with a new GC picking up around 2ppm of Ethylene. Martin may be able to provide some answers.

Prep seals are under construction in both MG and TG 7 Nth in the off chance that the situation develops into a serious heating event.

A decision has been made to seal the LW if 3.5ppm of Ethylene is detected. This is contrary to the 5ppm trigger point in the mine TARP.

I asked the mine if they had reviewed the situation which had occurred in 3/4 Nth. My understanding is that it was a similar situation and similar mine lay out i.e 2 x LW’s side by side. The mine said they had not and had difficulty in finding any information because of Insurance issues and confidentiality. I suggested the mine talk to Martin Watkinson and Darren Brady who were both involved at the time of this previous event.

I suggested that the mine prepare a process for taking gas bag samples from boreholes and ensure there are boreholes and sites available should the SIMTARS mobile lab be required and the mine is evacuated. This is a precautionary process in the event that an evacuation occurs and gas data from underground has to be gained from the surface.

The mine indicated that there is a swilly or water accumulation in TG 8 Nth which they are having trouble controlling. This would increase the pressure differential between TG 8 nth and the goaf of 7 Nth.

The mine is today taking a pressure survey of all the seals in TG 8 Nth to quantify the problem.

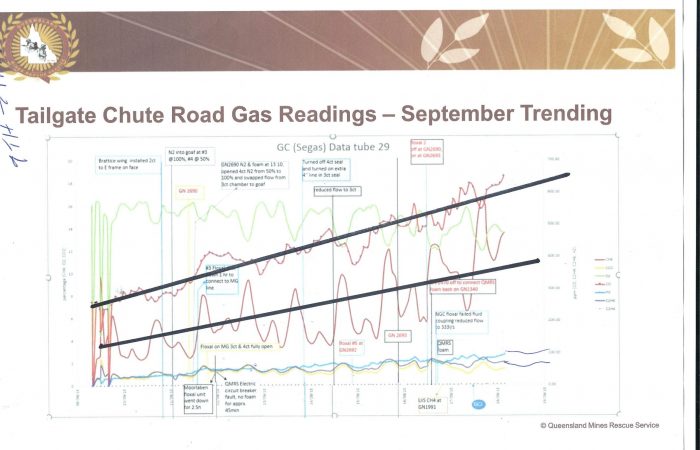

The mine continues to run the floxal inertisation unit and is presently injecting at both 7 and 8 c/t in MG 7 Nth. The CO readings are presently trending down.

The mine appears to have mitigating measures in place and a plan to protect the safety and health of people if the situation deteriorates. The CO appears to be trending down and steps are under way to locate the cause of the elevated CO and presence of the Ethylene.