North Goonyella Mine Fire MRE 2nd October 2018. “The 1:7 man and material Drift has been plugged with Rocsil foam of 350m3”

MRE – North Goonyella – 02.10.2018.pdf

On Tuesday 2 October 2018 Inspectors Geoff Nugent and Robert Sherwood attend the North

Goonyella Mine Accommodation Village to attend a meeting in regard to progress on dealing with the spontaneous combustion event, Inspectors arriving at 7:30am.

Update Meeting at 8:30am Tuesday 2 October 2018 Attendees —

Neville Impson (Compliance Manager), Jeff Perks (Superintendent Health Safety &Training) Dennis Black (Ventilation Officer), Steven Woods (ISHR)

Gareth Prichard (Electrical Maintenance Planner), Brendan Willman (Mechanical Maintenance Supervisor)

John Anger (SSE), Geoff Nugent (Mines Inspector), Rob Sherwood (Mines Inspector), Mike Carter (SSE Millennium)

Dial in — Marek Romenski (UMM), David Cliff (Consultant), Shaun Dobson (Deputy Chief Inspector)

John Anger (SSE) updated the meeting on the past last 24 hours and plans for the next 24 hours

Last 24 hours

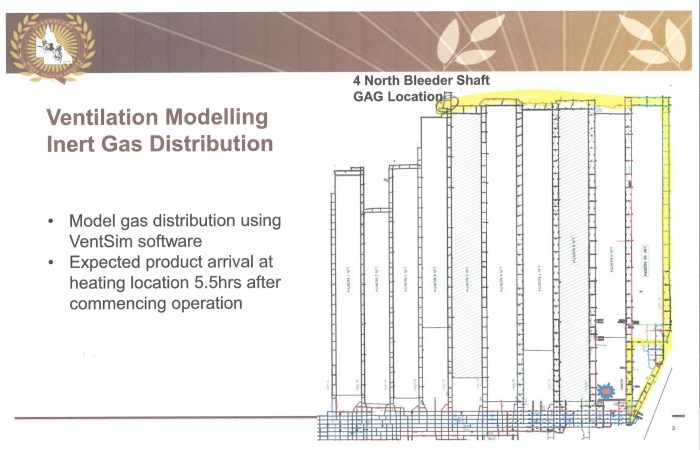

GAG has been running with no major issues

North Goonyella Coal (NGC) will continue Risk Assessment (RA) for dropping concrete down a borehole

NGC Conducting a RA for pumping Concrete

Several drone survey conducted during the previous day

The 1:7 man and material Drift has been plugged with Rocsil foam of 350m3

Bore hole GN2701 set-up with rods down to top of coal seam

Bore hole GN2704hrs drilled to 350.6m @ 05:00 hours Bore hole drilled to GN2703 38m

Pumped 4 trucks of concrete total 28m3 into 1:4 drift

Next 24 hr

Continue GAG operations

Plug H40 fan housing with rocsil

Install tube bundle monitoring point in H9 shaft

Continue drilling for LW containment

Continue concrete Plug drift portal

Meeting Notes

NGC will source engineering sign off for rated concrete seal in 1:4 drift portal, with a view to work through risk management process to remove exclusion zone around 1:4 drift.

On 1/10/2018 NGC landed drone on top of H40 ventilation shaft openings with streamer attached and observed no noticeable direction of ventilation flow indicting shaft potentially static.

David Cliff asked if bag samples would be taken after hole through of bore holes GN2701, GN2702 and GN2703. NGC would assess opportunity if holes breathing out and risk assessment provides acceptable controls.

NGC are working with QMRS to developing a strategy for establishing gas monitoring in bore holes via risk assessment process.

NGC are working on establishing a concrete batching plant outside exclusion zones and developing a transport strategy for concrete.