Ventilation Design, Methane HPI’s, Gas Characteristics Summary Grosvenor Mine 9th May 2018

The Mines Inspectors are challenging the Mine about the design of the Mine Ventilation System about why there is a bleeder road on intake.

I would go further and ask why employ a bleeder system at all?

The usual answer is that due to the block being cut short due to desire to be producing longwall coal as quickly as possible there is a in effect an unventiated single entry roadway until the next MG Development panel drives the face road and forms a ventilation circuit.

Poor planning and scheduling, production driven decisions

A bleeder shaft whether on return or intake was just an additional potential hazard at North Goonyella 5 South Spontaneous Combustion

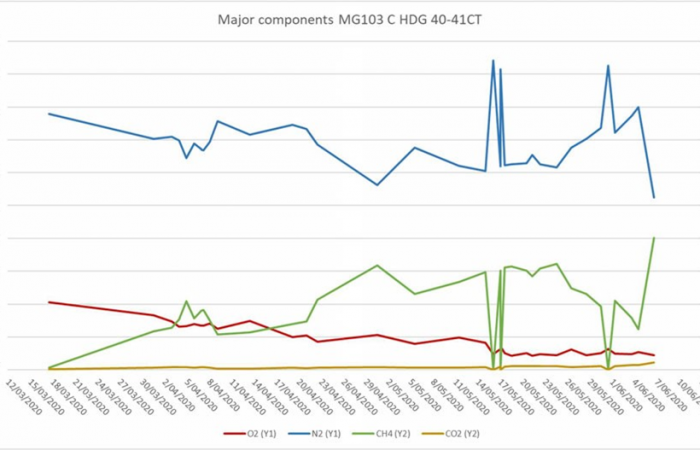

- Grosvenor mine had reported 32 HPl’s since LW 102 had commenced production in January 2018. This represehted 60% of all HPl’s in Queensland associated with Methane greater than 2.5% in Longwall TG

- Until the 400m sensor reads 5% (which is the Lower Explosive Limit) and stopping “haulage” production when the Shearer is in the Tailgate Shuffle Zone and the 400m Sensor reads 2% plus and leaving power onto shearer and cutting drums.

- Grosvenor employs bleeder road ventilation. The ‘Bleeder Road” intakes air around the perimeter of LW 101 along the bleeder road, past active goaf seals and mixes with intake air from the travel road.

- The TG methane level sits at 1.5% or above as the normal methane level. 0.4% methane intake pollution is a significant cause of the high Methane level in the TG general body.

- The goaf in the immediate tailgate area does not hang up and the goaf often rills in and impacts operation of/damages Chock #149

- The residual gas content of the coal in 102 LW, where the face position is currently is approximately 2 m/t. This is not particularly high and mines with higher gas content are having very few or no methane issues in the TG resulting in HPl’s with methane greater than 2.5%

- The last two HPl’s appeared to be a result of floor blowers in the goaf These coincided with high loading on LW shields and it is believed that this loading may be as a result of the thickening of overlying sandstone in the roof strata.

- Methane Blowers and “Floor Heave” events start occurring in Devolpment at roughly 20c/t in each panel

- Central Colliery had significant issues with floor blowers and had success by drilling UIS holes into the seam below. These holes did not produce a lot of gas but acted to relieve the pressure so that at times of cyclic loading the floor blowers were effectively eliminated.