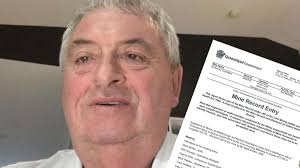

Allan Houston Fatality Court Proceedings. Will the Peak Downs ICAM Operator and Dozer Inundated with Water July 2018 be tendered as evidence in Court Proceedings?

When the court action commences against MR Fuller in relation to the fatal accident to Allan Houston will the ICAM from Peak Downs six months previously be introduced as evidence?

Peak Downs ICAM Dozer Aug 2018

The common and basic elements about no or inadequate risk assessments for working around water, water management and compliance to legislation are many.

The question has to and should be asked.

Why where the systematic and self identified BMA wide problems from July 2018 not immediately addressed by both Peak Downs, other BMA controlled Mines and RSHQ prior to December 2018?

Did the Asset production mandate to “keep the trucks running to meet production targets” arise at Saraji as it had at Peak Downs six months previously?

There is no doubt in my mind at all that Allan Houston would still be alive today if appropriate and timely action had of been taken by either BMA or RSHQ or both

Peak Downs and Saraji Mine are both operated by BMA and have directly adjoining leases.

They operate under the same BMA coal mine planning process, overarching BMA corporate SHMS and would seem to be bound by the mandates and requirements of something called the Asset for both production and safety.

If you word search the ICAM the impact of what the Asset requires both from a safety and production point of view is mentioned ten times excluding the attached timeline.

The production mandate of the Asset is spelt out quite explicitly in the partial timeline provided in the ICAM report.

In the timeline on page 29 of the 30 page document and marked as 29 of 44 pages there are the following comments

The timeline lists a Why question and the two answers for the 9th of July 2018.

Q. Why wasn’t pit preparation dewatering prioritised before operation in this instance?

A. There is a mandate to keep trucks running to meet production targets

A There is an asset requirement to have this mandate

Peak Downs ICAM Dozer Aug 2018

These are some of the common elements in the ICAM report.

- The ICAM team considered that these factors, combined with a specific strategy at the time of the event to optimise the mining of coal, could have contributed to the dozer operating in water and the event occurring.

- The operation did not effectively risk assess the hazard associated with working in & around water for mining activities despite it being recognised as a fatal risk for other activities at the site

- The risk assessment, performance standard and verification activities associated with working in and around water activities at Peak Downs have not sufficiently considered mining operation scenarios and the potential for significant events. There appears to be an acceptance of carrying out mining operations in shallow water without the application of all required controls. This is potentially is due to there being a perceived low risk of drowning when in the cab of a machine well above the water level, and doesn’t consider the risk when a machine traverses into an unknown deep void or topples where the cab may enter the water. The ICAM team acknowledged that within the mining industry there had been previous events where incidents related to dozers working in and around water resulted in near fatal outcomes. If the risks of carrying out mining operations in water had been better recognised and understood, and consequently better controls had been in place, it is possible that the event may have been avoided.

- The requirement for water management is not detailed on the mine plan that is signed off by the mining Supervisor or Superintendent prior to work commencing

- The operation did not effectively risk assess the hazard associated with working in & around water for mining activities despite it being recognised as a fatal risk for other activities at the site

Recommendation 3. To include mining activities in the fatal risk performance standard, including verification activities for working in and around water. Consider TARP controls within the mining process for mining in and around water, and document and embed within current practices and procedures.

Key findings

Organisational Factors for Processes and Systems

The asset has not provided clear guidelines for the requirements and accountabilities of water management through BMA coal mine planning or Peak Downs Mine’s SHMS

The asset has not provided clear guidelines for the requirements and accountabilities of water management through BMA coal mine planning or Peak Downs Mine’s SHMS

Will both BMA and RSHQ explain how they addressed or did not address the findings and recommendations of their respective Investigations into Peak Downs Dozer and Water HPI on the 9th July 2018 ?

Or will we just continue to see similar efforts as in the Grosvenor BOI where arbitrary dates are set that conveniently exclude pertinent information.

The Peak Downs HPI lists the only injury sustained as “In the process of exiting the dozer, the operator has sustained a minor laceration to their hand”.

It makes no mention about how serious the potential was, only that water entered the cab.

I am informed that by the time the ICAM was supplied to RSHQ the trapped operator had still not returned to work and did not ever return to work due to PTSD.

There is no mention how high the water rose in the cab and how much air pace was left before the operator was rescued.

There is not any mention of the efforts required to free the operator trapped in the cab.

From the details I have heard, the workmate who managed to free the operator should probably have been awarded a public medal as it was only due to his persistence and brute strength that he managed to break/remove high impact resistant glass and extracted the operator. This after wading/swimming through mud and water to get to the dozer.