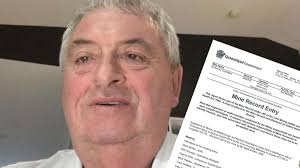

“I explained that it was not acceptable to move the LW Shearer when the general body Methane concentration in the TG return is equal to or greater than 2.5%.” Les Marlborough, Inspector of Mines. 20th October 2017

Today (20th October), I, Inspector of Mines, Leslie Marlborough, attended a meeting at Grosvenor mine to collect data requested from the mine in a postal mine record entry issued to the mine by myself on 13 October 2017. Attending the meeting were SSE and Mr Michael Webber, Ventilation Officer.

I provided a hard drive for SSE to transfer the gas data and other information onto, which he did. The screen shots requested were provided on PowerPoint slides which would be sufficient and the gas data was supplied as SPW files as requested by myself.

We held a discussion regarding the TG gas levels and the TARP which was the subject of a Directive issued by myself to the mine on 12 September 2017 and the subsequent response by the mine received on 3 October 2017.

I explained that it was not acceptable to move the LW Shearer when the general body Methane concentration in the TG return is equal to or greater than 2.5%.

I pointed out that the gas monitoring screen shots previously provided by the mine show that the shearer position in the Tailgate Shuffle zone does not generate excessive amounts of methane in the Tailgate.

The risk of methane ignition was discussed and I showed sketch drawings of TG layout with the air sweeping around the shearer and the likely methane concentrations to be found around the end of the TG AFC drive area.

SSE stated that the mine was holding a risk assessment to review the TARP the following week, with a view to revising the TARP to satisfy the terms of the Directive issued to the mine on 12 September 2017.

SSE stated that he was very aware that the next Longwall block may be different in gas characteristics as there will be an adjacent goaf alongside which the first Longwall did not have.

SSE explained the actions being taken by the mine in development to try to predict and minimise the effects of floor heave that had been experienced in the past. The mine is to be congratulated for its pro-active approach to this issue.

Explained it was unacceptable but did what? Actually did what ever?

Time for a total clean out of the tired, spent, complicit, corporately compliant, pathetically inept inappropriately name “Mines Inspectors.”

You know they’ve got nothing when even development superiors (new to industry supervisors) go “so” when it’s announced an Inspecter is on-site.

I can only agree.

All the words required to stop the activity is there.

Once an Inspector uses the words it “is not acceptable….” they have no choice but to issue a Directive prohibiting what is unacceptable.

Unfortunately it does not seem to rate a mention again in MRE;s I am in possession of.

This is where the Inquiry timeframes and all the Inspectors who actually Inspected Grosvenor not being called to give evidence makes sure the public are never aware of exactly what was going on at Grosvenor. How the Management and Inspectors walked hand in hand down the path to disaster gazing lovingly into each others eyes.

I was going to put a lot of comment but I would have been struggling not to swear a lot.

Your one sentence sums it up

“Time for a total clean out of the tired, spent, complicit, corporately compliant, pathetically inept inappropriately name “Mines Inspectors.”

Guys,

i think it is bigger than a clean out of people, it is a change of attitude within the department so they just don’t accept poor performance because the ones they have are the only ones they can get for the salaries on offer.

The good inspectors need to know when they do their job, if they upset people along the way they will be supported by their boss and not hung out to dry.

The deputy chief inspectors and the chief inspector need to have strength when Heads of operations from corporate office call or union executives call that they support their own staff.

you imagine being an inspector knowing if you stop a panel or a mine, you are then having defend your position to your supervisor because they are taking the position of the coal mine operator.

I could almost guarantee for an inspector to stop a panel or a mine because of an unacceptable level of risk, they have to get approval first.

This situation is caused in my opinion by the cooperation spoken of in the Act. – get rid of it.

Grosvenor is a prime example how the three parties working co operatively with the best interests of coal mine workers as their primary focus works.