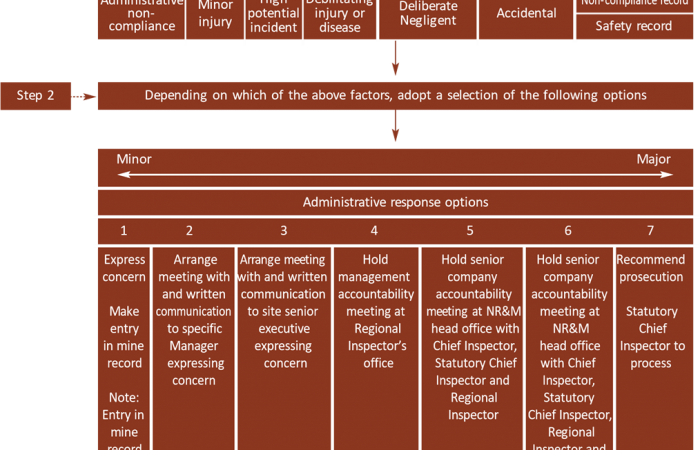

GROSVENOR SUBMISSION. ISSUE 5 (1) Whether the pre-drainage of gas from seams proximate to GMS was conducted adequately.

The 4 page submission is in the link below. Below is the first page and a half

Whether the pre-drainage of gas from seams proximate to GMS was conducted adequately.

This Submission is for Roof Strata Coal Seams Only. There will be a separate submission for Floor Seams.

FINDING

The methane pre-drainage system was conducted to only 25% of that required.

Reasons

1. Ventilation quantity of additional 200 cubic metres per second required to dilute 4.1 cubic metres per second to below 2%.

Would require approximately 275 cubic metres per second across the face to dilute goaf gas make. This is physically impossible.

2. Evidence of Ray Williams and Andrew Self. (Starts page 2)

1) Ventilation quantity required to dilute 4.1 cubic metres per second to below 2%.

Grosvenor by the LFI was extracting 4126 litres of Methane per second.

6.3 Goaf Drainage

Prior to the ignition, ten goaf wells were running, producing around 6425 l/s total flow, of which approximately 4126 l/s was methane. At 2:55pm on 6tl May 2020, only two of these wells were outside normal TARP, being well GR04V009 (44% methane, 9% oxygen) and well GR04V009.5 (31% methane, 14% oxygen). GR04V009.5 went into Level 2 TARP at approximately 14:40pm due to methane levels falling below 30% and the well was throttled back accordingly, reducing the flow and increasing methane purity (subsequently taking this out of Level 2 TARP).

To understand exactly how much methane we are talking about, it needs to be converted to CUBIC METRES per second, as all ventilation quantities are measured in cubic metres, so the mine is extracting 4.1m3/s of methane.

To deal with this quantity of methane in a ventilation circuit and keep it below 2% would require over 200 cubic metres per second of ventilation.

This is 3 times the quantity on the LW 104 face.

This around half the total ventilation of the Grosvenor Mine.

In effect the Mine is using the concept behind the back bleeder system as practised in the USA Mines but instead of using a sewer road and shaft they use multiple from the start of the block to within metres of the face.

An analogy would be having 10 people using straws, simultaneously sucking on a huge flat bottomed thickshake.

If they suck harder than the thick shake flow they will suck in air, not just at one place but 10 different places.

The first people who start sucking are people at the back of the thickshake.

They start sucking air first and suck air for the whole time.

RAY WILLIAMS and ANDREW SELF

Both Ray Williams and Andrew Self both stated that there was insufficient gas drainage of the P Seam.

ANDREW SELF

RAY WILLIAMS

Williams pointed out that Arrow energy is undertaken for commercial gas production often 10 to 15 years prior to Mining.

It is just as low a cost as possible gas extraction process not gas drainage.

It is not designed to perform gas drainage down to levels required for safe methane compliant Underground Longwall Mines.

The patterns and numbers of holes are designed for long term gas extraction, not methane drainage for Underground Coal Mining

Grosvenor Mine (and the Mines Inspectorate via Second Extraction Notices) for reasons known only to themselves; decided that the gas extraction performed by Arrow would ensure an acceptable level of Risk to the Safety and Health of Grosvenor Underground Coal Mineworkers.

Grosvenor

DR RAY WILLIAMS stated in testimony.

Yes. Arrow Energy undertook pre-drainage for commercial gas reasons some 10 to 15 years ahead of mining, and that was done without any regard to mining at all. They drilled in a manner that was the most efficient and least costly from their point of view.

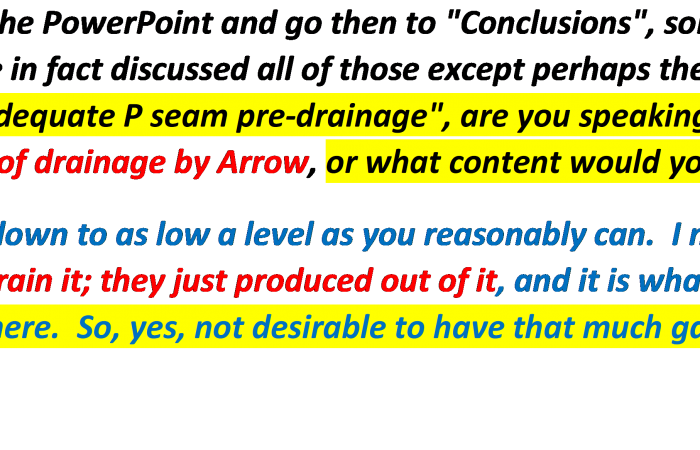

Q. Could we go back to the PowerPoint and go then to 37 “Conclusions”, some of which we have had a look at. I think we have in fact discussed all of those except perhaps the last one. When you have included there, “Inadequate P seam pre-drainage”, are you speaking there about inadequacies of the level of drainage by Arrow, or what content would you give it?

A. You want to reduce it down to as low a level as you reasonably can. I mean, Arrow pre-drained it – well, they didn’t pre-drain it; they just produced out of it, and it is what it is. Over longwall 104, there is still a lot of gas there. So, yes, not desirable to have that much gas in