I recall I engaged in a robust discussion with Mr Niehaus about corrective actions to manage the gas exceedances. We discussed the bleeder road and I suggested he consider putting the roadway on return.” Inspector Brennan Grosvenor Inquiry Statement. Never tendered at Grosvenor Inquiry. Inspector Brennan gave no evidence. Why not?

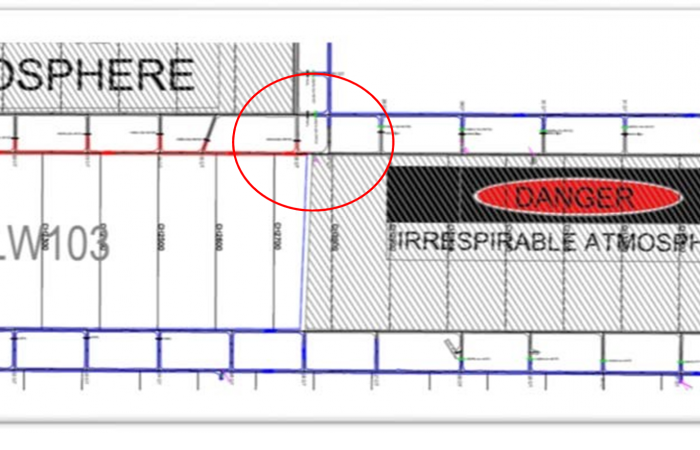

The bleeder shaft being intake and its negative effect on LW 104 spontaneous combustion likelihood and goaf fringe location received a lot of attention at the Grosvenor Inquiry.

The reason the bleeder shaft being on intake or return get more pertinent in LW 103 and LW 104 is that after a high number of methane HPI’s in LW 103, the Anglo Grosvenor Management at the urging of the Inspectorate change the bleeder shaft from intake to return.

Despite this Anglo revert to an intake bleeder shaft in LW 104 for the Grosvenor LW 104 Ventilation Arrangement (Little Britton LW Ventilation Arrangement).

How then does Anglo Grosvenor Management justify reverting back to an Intake Bleeder System for LW 104?

Why does the Inspectorate accept the Second workings Plans for LW 104 with an intake bleeder shaft in LW 104 for the Grosvenor LW 104 Ventilation Arrangement (Little Britton LW Ventilation Arrangement) with no written objection?

Why after Inspector Brennan makes a point of having “robust discussion with Mr Niehaus about corrective actions to manage the gas exceedances. We discussed the bleeder road and I suggested he consider putting the roadway on return” doesn’t the Inspectorate make Anglo Grosvenor retain the bleeder as a Return?

In my considered opinion the fact that that the HPI’s do not commence until LW103 is Retreating past LW102 Install face and as a result encountering a Super Stress Notch is directly and highly relevant to the events in LW 104 over 12 months later.

There is a change in the pressure differential and methane migration in the tailgate of the active LW 103 Goaf and the Adjacent Sealed LW102 and LW 101 blocks.

The 1st of the 29 Methane HPI’s on LW103 occur on the 18th of March 2019.

The Second HPI 3 days later on the 21st March identifies in OTHER INFORMATION DETAIL:

190321 a ventilation failure causing a dangerous accumulation of methane or other gas

LW103 is currently Retreating past LW102 Install face and as a result encountering a Super Stress Notch

The reason the bleeder shaft being on intake or return get more pertinent in LW 103 and LW 104 is that after a high number of methane HPI’s in LW 103, the Anglo Grosvenor Management at the urging of the Inspectorate change the bleeder shaft from intake to return.

Despite this Anglo revert to an intake bleeder shaft in LW 104 for the Grosvenor LW 104 Ventilation Arrangement (Little Britton LW Ventilation Arrangement).

Inspector Brennan was the relevant Inspector following Inspector Marlborough resignation from RSHQ (DNRME) after the North Goonyella Spontaneous Combustion, Fire, Explosion in later months of 2018.

Inspector Brennan prepared a Statement for the Grosvenor Inquiry that was never tendered as public evidence and for whatever reason Inspector Brennan was never called as a witness. I have attached a 6 page excerpt directly below

Why Inspector Brennan was not called to enter his Statement into Public Record and to provide verbal evidence is a question only the Grosvenor Inquiry, Counsel Assisting and RSHQ can answer.

The MRE also records that a blind bore shaft has been commenced to intersect 103/104 bleeder roadways by the end of the year. That was a measure that would improve ventilation to the face at longwall 104.

I recall I engaged in a robust discussion with Mr Niehaus about corrective actions to manage the gas exceedances. We discussed the bleeder road and I suggested he consider putting the roadway on return. I was aware if the mine placed the bleeder on return the change would reduce face ventilation by 20m3/s of ventilation across the face. To effect the change, ventilation modelling by the Ventilation Officer would be required to re-direct 20m3/s from another part of the ventilation system.

In other words, The change could not happen overnight, it would need to be planned. I also raised that the mine consider implementing uni-directional cutting, as opposed to bi-directional cutting, My reason for suggesting uni-di was that as less coal is cut* less gas is released in the cutting.

As a result of the robust conversation, Mr Niehaus volunteered to stand the longwall down for thirty-six hours (36 hours) and form an Incident Management Team (‘MT) to investigate changes that could be made to bring the gas exceedances under control, Standing a longwall down requires consideration of strata conditions, and the mine would have to plan it to ensure other hazards were not created.

The IMT minutes outlined both short and long term strategies to reduce gas exceedances on LW 103. These included:

-

- Short term ventilation changes and significantly from my point of view, the bleeder road ventilation change;

- Long term ventilation changes, including the additional shaft for LW 104 to assist ventilation;

- Short term goaf drainage strategies including an additional infill hole 90 metres from the main gate. I understood this to be an additional goaf drainage hole.

- Long term goaf drainage strategies, including installing additional blowers, and identifying potential goaf gas source areas for longwall 104.

At 7:44am on 11 July 2019 I received a telephone call from Mr Niehaus advising me that a HPI had occurred at Grosvenor Mine at 1 :36am. Mr Niehaus provided me with the details of the HPI. Upon review of the documents I recalled the longwall was down as [1]a consequence of an electrical issue when gas readings at the tailgate drive monitor started to rise, tripping power to the face.

Upon inspection, a floor blower between shields 55 and 56 towards the rear of the shields was located. A floor blower refers to pockets of gas from the Goonyella lower. Blowers can occur due to variations in the interburden between two seams. The shields supporting the roof occasionally may cause floor cracking resulting in the release of gas from the lower seam, During this conversation I recall the progress in relation to the implementation of the ventilation change I had suggested in early July.

On 6 August 2019 1 received a copy of a Form 5A sent by Grosvenor Mine in response to the HPI on 11 July 2019. 18 I read the Form 5A and it was consistent with the plans I was aware the mine had in place. I uploaded the Form 5A to Lotus Notes after I had considered it. The Form 5A included that the “gas make (SGE) was greater than expected in excess of system capacity. Less than adequate methane recovery / dilution LTA pre-drainage program in lower seam(s).”

The Form 5A also identified that the mine was identifying high risk floor gas release and was implementing a plan for floor gas drainage to remediate future areas of concern. This, together with the actions the mine had indicated in the IMT minutes [1] it proposed to take to improve drainage and ventilation, indicated that the mine had a plan to improve the situation,

The 1st of the 29 Methane HPI’s on LW103 occur on the 18th of March 2019.

The Second HPI 3 days later on the 21st March identifies in OTHER INFORMATION DETAIL:

190321 a ventilation failure causing a dangerous accumulation of methane or other gas

LW103 is currently Retreating past LW102 Install face and as a result encountering a Super Stress Notch

190321 a ventilation failure causing a dangerous accumulation of methane or other gas

At approximately 5:04am the shearer had cut out the TG area and was parked at shield #129. While advancing the TG shields stone rilled in from above shield #149 and closed off the face ventilation. The resulting restriction in the face ventilation and the scouring of the goaf resulted in the goaf gasses flushing into the roadway.

As per the attached graphs the CH4 readings in the TG recorded 2.62% CH4 on the inbye sensor and 2.85% on the outbye sensor in the LW TG.

Q Notwithstanding the development of this plan, the HPIs continued to occur, though?

A They did. They did. The initial suggestion of Inspector Brennan, which was for the mine to reverse the ventilation that was currently coming past longwalls 101, 102 and around the back of 103 into the face was bringing half a per cent of methane with it, and his suggestion and advice to the mine was that if they had a look at their ventilation management, they may be able to reduce that significantly by sending the ventilation the other way so that what was coming on to the longwall face was intake air at zero or 0.1 per cent methane. He made the point, if I recall correctly, that had that actually been the case, several of these exceedances would not have been

Q The ventilation change was implemented.

A It was.

Q. And it didn’t stop a recurrence of the HPIs, did it?

A. It didn’t – they did not cease. The nature of the HPIs following the ventilations changed compared to the ones pre the ventilation change.

Q. Go on, explain what you mean by that?

A. In terms of – the actual cause of the HPIs changed from being the shearer movement on the face, the shearer approaching the tailgate and the influence of the shearer on the ventilation across the face and consequently on what is drawn from the goaf. They were the first – they were the basic elements of the HPIs in early July. Subsequent to that, the ones in late July in general related to strata control issues that appeared on the face and in the tailgate for the mine to deal with.TRA.500.014.0061