My Submission “The merits of proactive inertisation by direct injection into the active goaf as a means of reducing the risk of spontaneous combustion and methane explosion.

This is the submission I sent to the Inquiry on Friday the 16th after some discussions and suggestions from one of the readers of my posts

There are two documents; Self and Ting is an attachment for the Formal Submission

Self and Ting Inertisation comments

7. The merits of proactive inertisation by direct injection into the active goaf as a means of reducing the risk of spontaneous combustion and methane explosion.

THERE IS LITTLE TO NO MERIT to ‘proactive inertisation by direct injection into the active goaf’ in normal longwall mining operations.

There would be some merit where the Longwall will likely be stationary for an unusually extended period of time for whatever reason. For example, breakdowns on longwall, geotechnical, conveyor belt damage or say COVID 19).

In methane rich mines it does not really matter which “artificial” Inertisation method is used, they all have drawbacks.

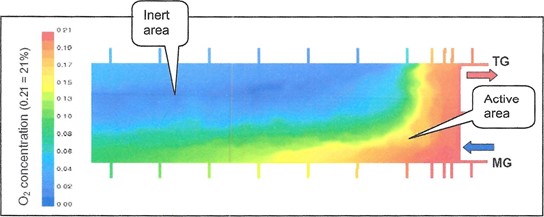

The best method of inertising the active goaf is to bring the inert fringe as close as possible, and safely, to the longwall face.

“Proactive inertisation by direct injection into the active goaf” is a detriment concerning spontaneous combustion monitoring detection.

The problem with proactive (constant) inertisation direct injection into the active goaf fall into three (3) broad PROVEN categories.

- Negative impacts on monitoring for spontaneous combustion due to the negative effects on the ratios used to detect spontaneous combustion.

- Masking and “Corruption” Effect of the products of oxidation

- Impractical. Impossible to achieve.

- Negative impacts on monitoring for spontaneous combustion due to the negative effects on the ratios used to detect spontaneous combustion.

I have collated the relevant comments of the respective testimony of

- Andrew Self Andrew Self – Consultant: coal mine systems Australian Coal Mining Consultants Pty Ltd

- Dr. Ting Ren – Associate Professor in Mining Engineering University of Wollongong

in the document “Self and Ting Ren Inertisation comments”.

There is also similar relevant testimony by Sean Muller (SIMTARS) which both witnesses refer to.

Self and Ting Inertisation comments

Some of the respective statements

Ting Ren

The standard indicators for spon com, like CO, hydrogen or ethylene or different trigger levels at different mines, they should be still applicable. So obviously when you do the goaf inertisation, you will disturb the process, the nature of the forming of the goaf atmosphere. You introduce contaminations to some of the parameters that you mentioned, the GR and also the Trickett’s ratio, because both GR and the Trickett’s ratio need to calculate the oxygen deficiency, to detect oxygen in the oxidation, and this is actually the measure of oxygen consumption. TRA.500.023.0021

2) Masking and “Corruption” Effect of the products of oxidation

This is an immediate problem once inertisation occurs.

Andrew Self

Q. So that shows the masking effect, if you like, on the amount of carbon monoxide —

A I’m calling this “corruption“. “Masking” is where the nitrogen gets in between the spontaneous combustion event and the monitoring point. This is where the products of combustion reach the monitoring point, as does the I don’t know if that’s pedantic.

Q Either way, the effect is to conceal from the person who’s looking at the

A One conceals it, and one leads to a false sense of security, and I think they’re two different things. TRA.500.021.0070

3) Impractical. Impossible to achieve.

The whole concept of constant active inertisation is little more than pipe dream fantasy.

In my post of the 29th,

“Proactive Inertization of “ACTIVE” Longwall Goaf is the topic at Grosvenor Inquiry 29th March. I am sure this will be nearly impossible to demonstrate as anywhere near practical or even possible by Inert Gas injection”

before Dr. Ren gave testimony I made the following comments which confirms that this concept of “proactive inertisation by direct injection into the active goaf

My views are unchanged and supported by the testimony of Self and Ren

It is practically impossible to use inert gas injection to inert the “ventilation wash” immediately behind the longwall face, particularly in the case of Grosvenor.

I wrote this post after generating this diagram that explains how this was even more impossible than other mines due to the “Little Britton” Ventilation Arrangement which explains why

If injected in the immediate Maingate and Tailgate volumes behind the face, it all disappears up the return roadway and out the main fan.

There is only one way to as far as practical/possible inert the active goaf of a methane rich mine.

Firstly you design the ventilation system so it is high flow low resistance as possible, to achieve the lowest pressure differential across the goaf.

This brings the inert fringe (low oxygen high methane) as close up to the face as possible. This denies as much coal as possible in the goaf, an atmosphere conducive to active spontaneous combustion.

Secondly keep mining so the inert fringe is advancing and not leaving coal in the wash for weeks at a time where the goaf atmosphere due to its high Oxygen levels and slow flow rates is ideally suited as conducive to Spontaneous Combustion

For those concerned about having the explosive fringe as close as possible to the back of the goaf and the tailgate roadway as possible, well that is nothing we have not done before without blowing a longwall mine up in Queensland.

Anglo’s now closed Central Colliery being a case in point.

The seam was not anywhere near as thick at Central Colliery (mined Stone to Stone).

It was the deepest mine with the highest in -situ methane content. (Had outburst in development)

Floor seam subject to sudden very large methane inrushes.

Near 100% pure methane in the back of the chocks in the tailgate.

Towards the end of the Mine, under then Mine Manager Phil Reed, they used methane injection to inert the goaf when they sealed a longwall panel.

They ran pipes from the underground methane drainage system into the final seals.

Stuart,

I think there is a time and place for proactive inertisation. as you mentioned Central colliery utilised methane quite well.

Andrew Self was pretty accurate with his evidence.

What is your recommendation? From an inquiry point of view are we asking for proactive inertisation to be scrapped, or are we asking for inertisation using products of combustion to be scrapped?

Coalhog, Thank You. It is always great and helpful getting discussion about these things. I am not going to pretend to have everything right in what I say

You are indeed correct. I should have said “little to no merit” in normal longwall mining operations.

In methane rich mines it does not really matter which “artificial” Inertisation method is used, they all have have drawbacks.

I will have to change a few words in my submission.

Thanks again for taking the time to read and contribute to the discussion.

If you have anything you think should be included in submissions, just let me know

Thanks again

I enjoy your site, its a pity there is not more discussion.

There must be plenty of people working in the industry that is interested in safety and making it safer.

I am looking forward to your secondary extraction submission, from an overview perspective this is probably the most important and hardest to get right.

Personally I think the Grosvenor environment was about as complex as I have come across, and legislation is not going to fix the management aspects present nor will it fix the mines dept.!

Coalhog;

That is why the secondary extraction will be one of the last ones I do.

I need to deal with just about every “key issue” issue first.

One thing about not too many people commenting is that I do not have to spend much time approving comments.

I do have a few people contact me, but most do so privately.

Several groups of people who will never, ever, ever comment already monitor my website and particularly documents I post;

trying to see if there is an electronic trail to try and find who the “leakers” are.

As well as checking out who comments and likes and who are my friends on Facebook

Coalhog. One thing I do know, the 100 year old way we structure the Mines Department Inspectors and how people get their Statutory Tickets is an old failed model. It has recently made even worse by what I hear was the deciding vote of the CIOCM Newman, A decision to not require Statutory Officials from other jurisdictions to even do a Qld Coal Mining Law Exam; let alone front a panel for an Oral Exam

Getting Managers and Inspectors who have never worked in Queensland under the current Act and Regulations , and Companies/Government to just happily appoint them has been wrong. Its been wrong for over 120 years in Queensland and counting.

When it comes to Inspectors I think it is time the old model is abandoned.

Firstly break it into Open Cut and Underground areas with Inspectors chiefly responsible for either Open Cut or Underground Mines.

Having a Deputy Chief Inspector (Open Cut) would establish clear lines

As for Inspectors lets go with people who are very experienced in actually working at the Coal Face. They already have Queensland Statutory qualifications; and they have had to apply the Act and Regulations, and what passes as the Mines Safety and Health System.

I am talking about Open Cut Examiners and Mine Deputies.