Proactive Inertization of “ACTIVE” Longwall Goaf is the topic at Grosvenor Inquiry 29th March. I am sure this will be nearly impossible to demonstrate as anywhere near practical or even possible by Inert Gas injection

Today at the Grosvenor Inquiry we are due to hear evidence and testimony from Dr. Ting Ren – Associate Professor in Mining Engineering University of Wollongong about

“Continuous inertisation of active goafs”

This I am sure, is going to be fascinating.

Given Grosvenor Mine Management seeming ignorance of the role of ventilation in spontaneous combustion and how to prevent leakage and unwanted airflows (include sealing off areas), increasing the resistance of leakage paths, and reducing ventilation pressure differentials this will be quite an exercise.

Let me be clear.

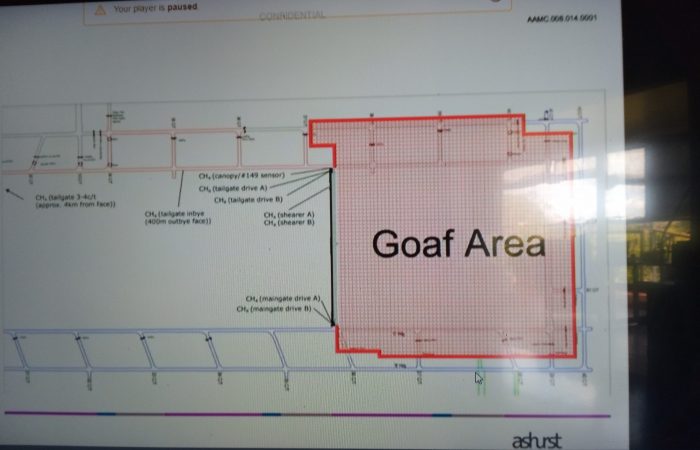

It is practically impossible to use inert gas injection to inert the “ventilation wash” immediately behind the longwall face, particularly in the case of Grosvenor.

If injected in the immediate Maingate and Tailgate volumes behind the face, it all disappears up the return roadway and out the main fan.

I note that Dr Ting Ren co-authored the paper with Jian Zhang (University of Wollongong), Hongtu Zhang, and Jianping Wei (Weifang University)

Whatever he has got to say I am sure to be fascinated how we are going to continuously inert an active coal mine goaf by inert gas injection into the goaf.

There is only one way to as far as practical/possible inert the active goaf of a methane rich mine.

Firstly you design the ventilation system so it is high flow low resistance as possible, to achieve the lowest pressure differential across the goaf.

This brings the inert fringe (low oxygen high methane) as close up to the face as possible. This denies as much coal as possible in the goaf, an atmosphere conducive to active spontaneous combustion.

Secondly keep mining so the inert fringe is advancing and not leaving coal in the wash for weeks at a time where the goaf atmosphere due to its high Oxygen levels and slow flow rates is ideally suited as conducive to Spontaneous Combustion

For those concerned about having the explosive fringe as close as possible to the back of the goaf and the tailgate roadway as possible, well that is nothing we have not done before without blowing a longwall mine up in Queensland.

Ask anyone who worked on the Anglo Coal Central Colliery Longwall face where the explosive fringe was?

No doubt we are going to hear about the use of fly ash, chemical foams, and slurries from a range of materials to fill voids and block air paths in the goaf.

This is nothing new.

It has been trialed in Europe and China at least over the last couple of decades.

Given Grosvenor Management track record if they tried to inject flay ash or a cement slurry from the surface, it would be down the wrong borehole and would probably end up encasing the tailgate chocks in cement slurry.

I will not even discuss the logistics involved in getting enough fly ash or slurry to Moranbah to even conduct a trial.

How many tonnes of coal will be mined for each cubic metre of fly ash or slurry?

Pure fantasy in my view, but sounds impressive in a Research Paper

The quantities of fly ash or slurry involved would be massive.

I have located a paper Dr Ren co-authored in 2005 with Rao Balusu (CSIRO Exploration and Mining) and Pat Humphries (CSIRO Exploration and Mining)

It is in relation to inerting a recently sealed goaf after the longwall has been removed.

Newlands Mine in Queensland part of Study

Stuart, what am i missing in this Inquiry?

The 104 longwall panel was reasonably short, and we all know that until the longwall has retreated a significant distance (full subsidence on the surface is a good indicator), goaf behavior is different to a normal operating longwall face. an old pommy taught me that a good rule of thumb was to ‘square’ the goaf.

There appears to be to much expert evidence on a normal longwall face, rather than the issues of starting a longwall panel, and the challenges it presents.

Talk of inertising the active goaf is not the same if this panel was 1500m long and had 103 goaf beside them.

I don’t know if this is a deliberate tactic by the legal teams, or whether it is a product of the lack of practical experience at the inquiry.

All I know, when I have worked as a longwall coordinator , until the goaf consolidated and ventilation normalised and became predictable, many stressful times were had.

Coal Hog,

Squaring the goaf and the relatively small goaf has just gone through to the keeper. I have listened to most of the evidence and I cannot remember it coming up.

Particularly when you are trying so suck the guts of it out via goaf drainage holes (7.5m3/s rings a bell).

They are really only trying to do what the mines in the USA do with their back bleeder system.

Only problem is that they are deliberately sucking the guts out of the goaf.

From what I understand of the USA back bleeder is that they just allow ventilation pressure differential to try and draw the excess methane out of the goaf and so except for barometric influence they try and keep it in a steady state.

Using an exhaust ventilation fan and having to run it below 1.25%, would need to be a pretty big fan.

If you want to dilute 5m3/s of excess methane your face ventilation cannot handle to 1.25% general body, the Mine would need 400m3/s going up through the USA style back bleeder road and shaft.

Though on evidence so far, all that Grosvenor Management would have done if they attempted this would be to put an explosive mixture through the bleeder fan

The whole mine runs on around 450m/s at main fans.

All this rubbish being spouted in the Inquiry.

The best remedy for all the problems is to reduce methane levels in the coal seams via gas drainage.

If it is too gassy this year, maybe in 12 months or 2 or 5 years it will be an acceptable level of risk to mineworkers to commence Longwall operations

I think the Americans are very good coal miners, doesn’t mean we should follow what they do unless the underlying principles are understood. an example is that legislation in the US isnt on preventing ignitions, The practice is about getting good of putting fires out. Imagine that philosophy in Qld.

There are lots of things the mine could of done, being a monday night quarterback doesnt alter the fact of where the mine is and more broadly the industry is.

I would be interested in seeing if the inquiry looks at how the mine got to this point. Economic cost analysis would be the driver, the decision to put the back of panel shaft in for cooling purposes is a key component of the decision making over the past two years that has impacted the situation.

Capital expenditure is so tightly controlled in some organisations that the best decision is not made.

I think if the inquiry spends sometime to see how organisation decisions two years ago were made in relation to risk management and mitigation, the industry might change for the better.

CoalHog;

The Terms of Reference Minister Lynham wrote, are in my view deliberately restrictive so all the sorts of things you are talking about do not even get a mention.

It was the newest longwall Mine in the State and supposedly the best technology.

Everything about the Mine, from final design and driving the drifts onward, falls within the 7 year timeframe where Mine Records must be kept.

Of course that would mean the Mines Department opening up its records as well and being open to scrutiny.

All the issues Grosvenor had with methane would be on the table, not from this deliberately chosen, artificial time.

All the nearly industry wide under reporting of Methane HPI’s.

Not the changes to Methane Regulations in February 2020.

Not to the Interpretations of the Act and Regulations from the immediately former (who went to work as Technical Service Manager with Anglo) and current Chief Inspectors.

When I finally cornered Peter Newman the current CIOCM in a private meeting room at the Grosvenor Inquiry, he could not just ignore me and refuse to answer my correspondence.

He admitted what I had already asked him in writing and on the phone, and what I already knew.

He has never worked in Queensland as an Underground Mine Manager since the 1999 Act and 2001 Regulations came into effect. (Bit hard when you have spent the last 15 odd years in NSW).

Also when I asked him whether he ever got any legal advice before he issued anything relating to Interpretations of the Acta nd Regulations.

He strongly asserted there was no need to. He was the Chief Inspector and knew what he was doing.

To cut a long exchange short lets just say I politely told him that the lack of “appropriate legal advice was quite obvious”.

In any of the few formal replies it was quite clear he did not understand how the Act and Regulations work.

“Anyone sitting the Law Exam who gave answers like he gave would get an instant fail” I told him

I am definitely not advocating the USA system as there have been enough examples of them setting longwall mines on fire.

One mate of mine still has a nickname of “Captain America” from getting sent to USA with the GAG jet engine to Loveridge Mine Fire in 2003.

He only got to Brisbane and Glencore/Xstrata decided he was too valuable to risk in America and cancelled his flight.

https://www.miningmonthly.com/sustainability/international-coal-news/1302557/gag-goes-usa

The reason they do it is because the methane has not been drained adequately. This is their way of short cutting to being able to “safely” mine and not keep putting potentially explosive mixtures of methane on the face.

They then run into the problem of inducing spon com by continuously feeding oxygen into the goaf.

As we know North Goonyella ran 5 Sth Longwall with an exhaust bleeder fan.

I am convinced Nth Goonyella would have been far easier to manage with a trickle of intake from the back

The decision to turn off back bleeder for the exact reason bringing the fringe forward, and mine filled the shaft with dirt/rocks.

However by then it was too late, and the heating too advanced and it effectively took control of ventilation flows in the goaf.

Every thing is a balancing act when it comes to ventilation as you know.

Some things possible some not

No Ventilation system can successfully juggle 25 different size balls, knives and flaming torches at once.

Drain the methane so your conventional ventilation system can deal with the goaf methane make and twice daily barometer cycle is the only answer

I think it will be neglectful, if the inquiry does not focus some of their time on the conditions that were prevalent at the time of the ignition ie start of panel.