![According To CW-5, A Peabody Employee Informed Him That Peabody “[expletive] Up Some Of The Ventilation” And This Caused A Heating That Peabody Then “did Not Handle As Well As They Could Have.”CW-5 Project Manager And Engineer With A Focus On Longwall Move Optimization,](https://www.qldminingcrisis.com.au/wp-content/uploads/2021/03/Profit.jpg)

According to CW-5, a Peabody employee informed him that Peabody “[expletive] up some of the ventilation” and this caused a heating that Peabody then “did not handle as well as they could have.”CW-5 Project Manager and Engineer with a focus on Longwall Move Optimization,

2021-03-19 – 0038 PEABODY ENERGY – AMENDED COMPLAINT (3023799.1) (1)

64. CW-5 was employed at Peabody from before the Class Period through early summer 2018. CW-5 served as a Project Manager and Engineer with a focus on Longwall Move Optimization, including at North Goonyella. CW-5 frequently traveled to North Goonyella as part of his responsibilities at Peabody and reviewed longwall plans as part of his expertise.

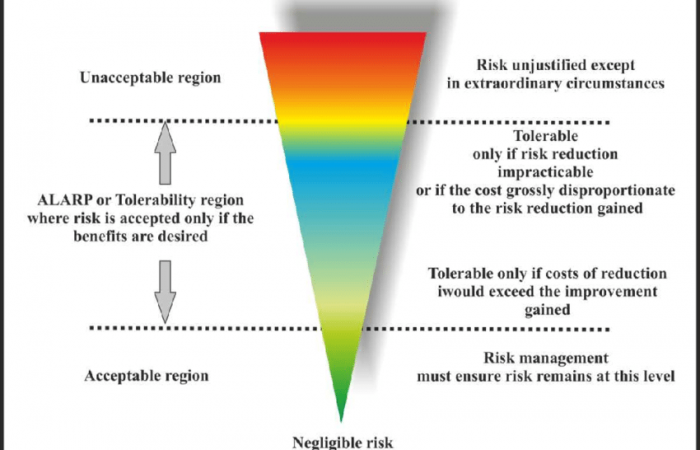

76. CW-5 advised that the underground in Queensland, Australia (where the North Goonyella mine is located) is “notoriously gassy” and that there is the opportunity for a dangerous situation due to the inherent risk level of the mine conditions. CW-5 explained that the ventilation engineer at North Goonyella needs to be “on top of his game” as the coal has a propensity to combust and is arguably the most dangerous in the world.

83. According to CW-5, the Peabody culture was to “push the boundaries of what was safe.” CW-5 explained that the mine staff was always being “beaten down by Mother Nature and Peabody Management.” CW-5 advised that Peabody’s management was always thinking “money, money, money.” CW-5 noted that he did not agree with the way the Company operated and he doubted Peabody management could even “run a small business in the outside world.”

84. CW-5 explained that Peabody management dictated what happened on the mine site and applied pressure on mine management, despite being nowhere near the realities of the mine. CW-5 recalled Peabody management always “pushing for more.” CW-5 gave the example that if mine staff were to say the mine could produce 2 million tons of coal annually, Peabody would tell the shareholders it could produce 3 million tons annually. CW-5 explained that these unrealistic expectations put tremendous pressure on mine staff and led to bad decision making.

85. CW-5 explained that Peabody “continuously misses on the small things” and “following the plan in place wasn’t their strong suit” in regard to the staff at North Goonyella. CW-5 recalled witnessing North Goonyella staff missing small things on numerous occasions.

89. Further exacerbating personnel issues at the mine was the fact that remaining staff were long tenured and high paid, thus replacement personnel were typically hired on the cheap – and were mostly younger and inexperienced mine workers

e) CW-5 recalled that Peabody had parted ways with an expert ventilation engineer with 15-20 years of experience while CW-5 was an employee. CW-5 advised that Peabody had shifted towards hiring naive and inexperienced employees who did not know the mine well and were not aware of the constant level of danger.

99. CW-5 recalled that following the combustion event at North Goonyella he called several of his former colleagues who were working at the mine at the time and he was told that they didn’t follow the longwall plan. According to CW-5, a Peabody employee informed him that Peabody “[expletive] up some of the ventilation” and this caused a heating that Peabody then “did not handle as well as they could have.”

100. CW-5 advised in cases where the longwall was moved too soon, there would likely be incident reports.

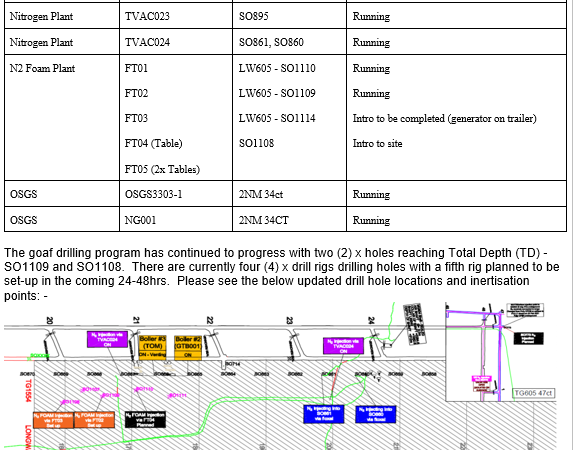

103. CW-5 confirmed that if there was a reading of Ethylene in North Goonyella, this was a “red flag” because Ethylene is “a fair way down the combustion curve.” CW-5 explained that the presence of Ethylene should warrant an investigation immediately as it may be the leading indicator that there is a fire.