Methane Inrush from Floor Blowers in Longwall Panels. Forward Abutment Pressure.

An Inrush is defined under the coal Mine Regulations as

inrush means an unplanned or uncontrolled flood of liquid, gas or material that has the potential to create a hazard.

As we have already established there are methane inrushes in development inbye roughly 21c/t in the 103 and 104 gate-roads with at least 8 in 2018 and 2019.

We also know that there has been methane blowers mid-face at Grosvenor that released over 2460 cubic metres in an hour that have resulted in the reporting of an HPI.

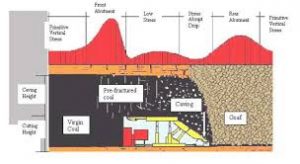

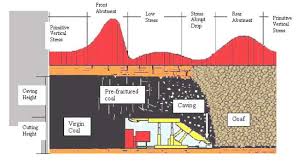

Without getting into the geo-mechanical science involved the stress loads resulting from the removal of the coal is transferred onto the remaining coal block.

On the longwall face there is a zone called the forward abutment zone.

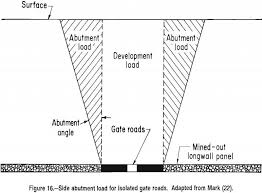

There are also the side abutment load that act on the chain pillars.

One reason that the Tailgate of a Longwall suffers the most from roof and floor instability is having the side abutment pressure of 2 longwalls acting on the single chain pillar so it is by far the highest stress load. You have to remember at least the first 5 m of the pillar carries no load so the effective size of the chain pillar is reduced.

The forward abutment zone maximum load generally occurs within 5 to 10 metres of the face.

It is in this zone that it is most likely that a methane inrush would occur.

If the longwall is operating I would think that there is a fair chance that no one would notice it on the face. In development all they mention is hearing and feeling a bump.

If there is 5 to 10 metres of coal between the face and the floor blower it would not be noticed by noise, just more methane bleeding off the face.

Also it is my experience that these occur more often towards and in the tailgate roadway themselves as they did at Central Colliery.

There would however be one good indicator.

If there was no noticeable on the LW Tailgate Sensor (Section 243 (a)) located at Chock number 149 yet the 400m sensor in the tailgate has sudden major increases, the gas has come from somewhere.

My gut feel is that methane inrushes occur much more frequently than Grosvenor Mines Recognize.

The Mine itself notes how hard the Floor Seam is to drain.

It would be logical that when the floor ruptures that only the gas in the immediate area/volume would release.

I would bet that there are a relatively large number of methane HPI’s incidents and near HPI incidents where the Section 243 (a) sensor barely alters at Grosvenor Mine that have been either misunderstood, not noticed or ignored.

Only a proper examination of the continuous gas trend data could tell