North Goonyella Mine Fire 25th September 2018. “Discuss course of action, (inc.DNMRE representation), which includes drilling holes to enable remote sealing of LW9N”” Review exclusion zones for explosibility at surface areas with intent remove based on current readings.”

MRE – North Goonyella – 25.09.2018.pdf

The confirmed presence of Ethylene (C2H4) precipitates a number of IMT (Incident Management Teams) meetings including one at 2pm.

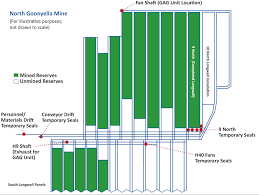

The Mines Inspector now wishes to include the drilling of boreholes to remotely seal 9 Nth Longwall panel.

By the looks of things and as events prove the Sealing LW9N Horse Remotely has bolted after Closing The Prep Seal Horse”.

- Validation sample of high TB38 (E-frame) H2, CO, C2H4 confirmed and subsequent meeting held at 11:58 to discuss course of action, (inc.DNMRE representation), which includes drilling holes to enable remote sealing of LW9N

- Follow up meeting held at 13:00pm which included discussion around reduction of gas levels at TB38

- 14:00 Meeting with DNMRE Inspectorate

At the conclusion

Strategic focus today for NGC:

Review exclusion zones for explosibility at surface areas with intent remove based on current readings.

The situation continues to deteriorate.

The presence of Ethylene at the E Frame (tube 38).

High levels of Hydrogen.

“Results from TB14 are not consistent with results from TB38 relative to trend and barometer”

CO past TB 14 needs to be seen to be not replenishing before an assessment can be made heating is arrested.

Discussed the influence of high H2 on the Oxygen Nose Point in current samples and to ensure it is considered when assessing explosibility risk.

“Potentially 02 is still being supplied to Goaf, focus and inspection will be conducted on adjacent Goafs 8 and 7”

Recommend NGC immediately develop a risk based SOP to be applied by CMW’s when conducting tasks around boreholes and handling bag samples and collecting bag samples where excessive gas concentrations may be present.

Extracts from the MRE

- Validation sample of high TB38 (E-frame) H2, CO, C2H4 confirmed and subsequent meeting held at 11:58 to discuss course of action, (inc.DNMRE representation), which includes drilling holes to enable remote sealing of LW9N

- Follow up meeting held at 13:00pm which included discussion around reduction of gas levels at TB38

- 14:00 Meeting with DNMRE Inspectorate

Next 24

Meeting Notes

- Floxal current capacity 2m3/s more capacity being installed today with Narrabri unit quantity yet to be determined.

- NGC management team provided presentation to workforce re status of event each day. Marek Romenski discussing re-entry plan

- Acetylene has been identify in samples and SIMTARS will have fire span gas to test for higher hydro carbons once mobile lab arrives.

- Results from TB14 are not consistent with results from TB38 relative to trend and barometer. To be analysed by technical experts

- Concern raised about exposure of CMW’s working around boreholes and processing bag samples with potential exposure to excessive concentrations of CO and other contaminants when boreholes breathe out and bag samples being purged. Recommend NGC immediately develop a risk based SOP to be applied by CMW’s when conducting tasks around boreholes and handling bag samples and collecting bag samples where excessive gas concentrations may be present.

Lee Earnshaw delivered workforce presentation and discussed a number of considerations re-entry strategy and risk assessment.

Darren Brady recommended most effective location for majority of N2 to be applied is GN2470 e Potentially 02 is still being supplied to Goaf, focus and inspection will be conducted on adjacent Goafs 8 and 7.

- CO past TB 14 needs to be seen to be not replenishing before an assessment can be made heating is arrested.

Discussed the influence of high H2 on the Oxygen Nose Point in current samples and to ensure it is considered when assessing explosibility risk.

Strategic focus today for NGC:

- Review exclusion zones for explosibility at surface areas with intent remove based on current readings.

- Most effective application of N2 strategy to be confirmed by EMT

- Develop drilling strategy to consider; Floxal injection, appropriate monitoring points and contingency for sealing if required.

On Tuesday 25 September 2018 Inspectors Geoff Nugent and Keith Brennan attend the North Goonyella Mine to attend a meeting in regard to progress on dealing with the spontaneous combustion event, Inspectors arriving at 7:50am.

Update Meeting at 8:30am Tuesday 25 September 2018

Meeting Attendees:-

John Pearson (SSHR), Andy Hislop (GM Metropolitan colliery NSW), Jeff Perks (Superintendent Health

Safety &Training), Marek Romenski (UMM), Nev Impson (Compliance Manager), John Anger (SSE)

Keith Brennan (Mines Inspector), Geoff Nugent (Mines Inspector), Steven Stook (Tech Services

Manager), John Deacon (Development Superintendent), Jason (lien (LW Superintendent)

Lee Earnshaw (Development coordinator), Peter Baker (Peabody Operations Manager), Alex Wilson (SIMTARS), sean Mueller (SIMTARS)

Dial in: Sean Dobson (Deputy Chief Inspector) Michael Brady (Consultant) Darren Brady (Consultant), Martin Watkinson (SIMTARS), Mike Carter (SSE Millennium), George Schuller (GM Peabody Aust. Operations)

Last 24

- Drilling GN2700 – completed hole through at 3:30am and rods out of hole and capped at 5:00am Drilling GN2699 – drilled down to 295m loosing circulation DS only operation, at end of shift pulled rods back inside casing at 222m

- Drilling 2696 – completed drill out of hole and re-established casing – hole still stagnant, lifted the casing up by 18m and hole started sucking proving connectivity Delivery of 3rd Narrabri unit

At EOS NS, the Floxal status indicates an overall increase of 411/s from 3am NS 24/9/18 RE-ENTRY PLAN : RA – Control of risk to surface personnel following sealing of LW9N TG chute road – reviewed to include trigger for re-entry

CS Gas – (work over rig for installing Rocsil remote sealing system), demobilised off site

- Validation sample of high TB38 (E-frame) H2, CO, C2H4 confirmed and subsequent meeting held at 11:58 to discuss course of action, (inc.DNMRE representation), which includes drilling holes to enable remote sealing of LW9N

- Follow up meeting held at 13:00pm which included discussion around reduction of gas levels at TB38

- 10 14:00 Meeting with DNMRE Inspectorate

Next 24

- Tuesday 25th September – Floxal maintenance planned

- Re-establish GC facility and calibrate with high CO span gas —LW development office SIMTARS mobile lab to arrive on site

- Continue filling in Mine Re-entry Assessment System (MRAS) questionnaire, 5 modules completed Finalise floxal distribution plan, including additional holes on the basis of gas trends and inertisation strategy

- Remove exclusion zone based on bag samples tested for explosibility

- RE-ENTRY PLAN : RA – chute road sealing (to allow underground entry to extract LW9N supports) review plan

- RE-ENTRY PLAN : RA – chute road sealing (to allow underground entry to extract LW9N supports) review WRAC

- Take Bag samples from TB#14, TB#38 on a 2 hourly basis

- Site preparation for GN2702 (MG Belt Road) and GN2703 (MG9N 2 ct A-B hdg.) – which are contingency holes in case of a panel seal up : relocate rig 1218 to GN2702 Drilling GN2702 with Rig 1218 (2nd DI-AM and BHA available)

- Drilling GN2701 with Rig 1226 (DHM equipment from rig 1218 relocated to rig 1226) (currently down 30m)

- Prepare set-up for re-drill GN2690 with TX130 Schramm (Rig 1265) and re-enter hole with the view to increase depth – anticipate start up approximately mid day and requires modification of access to main Floxal area. Review modification of traffic management plan

- Set up 3rd Narrabri unit

Install tube bundle monitoring point in GN2700 (inbye of Rocsil seal at TG Chute road) T30 (1m from roof) and TB31 (2.5m from roof) Floxal Strategy

- Finalise floxal distribution plan, including additional holes on the basis of gas trends and inertisation strategy

Meeting Notes

- Floxal current capacity 2m3/s more capacity being installed today with Narrabri unit quantity yet to be determined.

- NGC management team provided presentation to workforce re status of event each day. Marek Romenski discussing re-entry plan

- Acetylene has been identify in samples and SIMTARS will have fire span gas to test for higher hydro carbons once mobile lab arrives.

- Results from TB14 are not consistent with results from TB38 relative to trend and barometer. To be analysed by technical experts

- Concern raised about exposure of CMW’s working around boreholes and processing bag samples with potential exposure to excessive concentrations of CO and other contaminants when boreholes breathe out and bag samples being purged. Recommend NGC immediately develop a risk based SOP to be applied by CMW’s when conducting tasks around boreholes and handling bag samples and collecting bag samples where excessive gas concentrations may be present.

Lee Earnshaw delivered workforce presentation and discussed a number of considerations re-entry strategy and risk assessment.

Darren Brady recommended most effective location for majority of N2 to be applied is GN2470 e Potentially 02 is still being supplied to Goaf, focus and inspection will be conducted on adjacent Goafs 8 and 7.

- CO past TB 14 needs to be seen to be not replenishing before an assessment can be made heating is arrested.

Discussed the influence of high H2 on the Oxygen Nose Point in current samples and to ensure it is considered when assessing explosibility risk.

Strategic focus today for NGC:

- Review exclusion zones for explosibility at surface areas with intent remove based on current readings.

- Most effective application of N2 strategy to be confirmed by EMT

- Develop drilling strategy to consider; Floxal injection, appropriate monitoring points and contingency for sealing if required.