Developments in the Management of Spontaneous Combustion in Australian Underground Coal Mines by David Cliff , Darren Brady and Martin Watkinson. How does Grosvenor Mine and “‘Little Britton” Longwall Ventilation compare?

Developments in the Management of Spontaneous Combustion in Australian Underground Coal

Mines by David Cliff (U of Q), Darren Brady (ex SIMTARS now a consultant) and Martin Watkinson (SIMTARS)

This is a paper jointly delivered by 3 of the Consultants/Researchers that have either given evidence at the Grosvenor Inquiry (Watkinson SIMTARS) or been referred to in Dr. David Cliff (MISHC) and Mr Darren Brady.

It was delivered in 2014 at the annual Coal Operators Conference, held in Wollongong each year.

It is not overly long at 10 pages

Developments in the Management of Spontaneous Combustion in Austr

It does contain a number of relevant statements that do need mentioning.

1 ) Proactive Controls- Mine Design

2) Hazard Management Plans

3) TARPS

4) Mine Design Guideline MDG1006

I shall look at MDG 1006 in a subsequent posts

PROACTIVE CONTROLS

Probably the most important area of improvement in the control of spontaneous combustion in underground coal mines is the prevention of spontaneous combustion through appropriate design of mining operations.

Computational fluid dynamic modelling, coupled with control over pressure differentials around goafs and proactive application of inertisation, has reduced the potential for oxidation to occur in sealed areas (Ren and Baluso, 2005; Balusu, et al., 2010).

These techniques are assuming increasing importance as longwall panels become wider and longer and thicker seams are mined.

Modelling has also enabled the potential impacts of goaf gas drainage on the distribution of gases in the goaf to be evaluated, as well as scouring of the goaf due to high face ventilation quantities and pressure differences (Ren, et al., 2005; Balusu, et al., 2010).

Ventilation models are able to evaluate the pressure changes around mining panels under various configurations, including two or three gate roads and bleeder roadways. The modelling has been validated using tracer gas studies (Luxbacher and Jong, 2013).

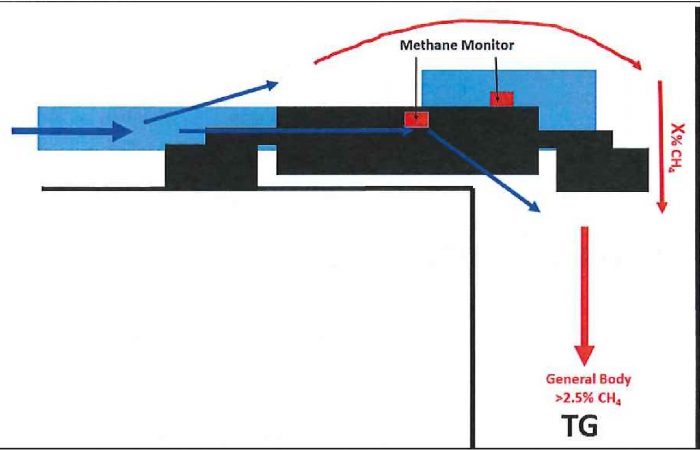

A number of mines now minimise air ingress into active longwall goafs by constructing pressure balancing chambers in gate-road seals. These chambers can be linked to remove any pressure differential between seals, or they can be pressurised with inert gas to prevent air ingress (Brady, et al., 2008).

HAZARD MANAGEMENT PLANS

A consequence of the Moura No.2 mine disaster was the reform of the coal mining safety and health legislation in NSW and Queensland to include the requirement for principal/major hazard management plans to control the risk due to spontaneous combustion.

This facilitated a more systematic control approach whereby risk management principles were applied and mines had to demonstrate that they had assessed the potential for spontaneous combustion, identified the controls required.

These plans must then outline the details of how the controls would be implemented and how their effectiveness would be monitored. Consistent with AS4804:2001, Occupational Health and Safety Management Systems – General Guidelines on principles, systems and supporting techniques, the plans must then identify key responsibilities, resourcing requirements and training needs.

To provide guidance in developing these plans the then NSW Department of Industry and Innovation, issued a revised Mine Design Guideline MDG1006 with an accompanying technical reference guide (TRG) (NSW DII, 2011a and b). The TRG is an excellent and detailed technical reference document, and includes details of 23 incidents that have occurred since 1970