Westcliffe 1986 PUR Fire Report Evidence, Finding and Contraventions

https://www.qldminingcrisis.com.au/wp-content/uploads/2021/02/westcliff-incident-report-part-a.pdf

During the current tranche of Grosvenor Mine Inquiry there has been mention of the relevance of the 1986 Westcliffe PUR fire that occurred on the 13th December to Grosvenor.

Westcliffe was the first known incidence of a fire due to inappropriate use of PUR.

There are a number of differences that I will go into in later posts.

Biggest things to note is how quickly the fire developed

The thick smoke and fumes generated from both curing and burning PUR.

How difficult the fire was to put out. Fire extinguishers and stonedust had no effect.

Using water was lengthy and difficult and the PUR had a tendency to quickly re-ignite

The Official Investigation was conducted by Ron Smith, Senior Inspector of Coal Mines and he release his Report on the 13th March 1987, four months after the fire

He found contraventions by the Underground Mine Manager and Chemfix.

- The Mine Manager was negligent in that he failed to recognise the conditions of the Approval No MDA Non-Ex 1469 and did in using the polyurethane contrary to approval conditions endanger the safety of the mine and persons therein

2) Arnall-Wickman Pty Ltd was negligent in that they failed to comply with the conditions imposed in the Approval No MDA Non-Ex 1469 and in so doing did endanger the safety of the mine and persons therein

Section 160 (l)

Arnall-Wickman failed to comply with Provisions of the Act in that they contravened “Coal Mines Regulation (Approval of Items) Regulation 1984 Clause 6 (4) (c)

Section 160 (n) (o)

Arnall-Wickman failed to comply with a direction given to them by Chief Inspector in that they did not comply with a condition imposed on them in accordance with a provision of the Act

The face Deputy in charge of the 4 hour fire watch on the 13th of December provided a statement.

West Cliff Deputy Peter Forbes

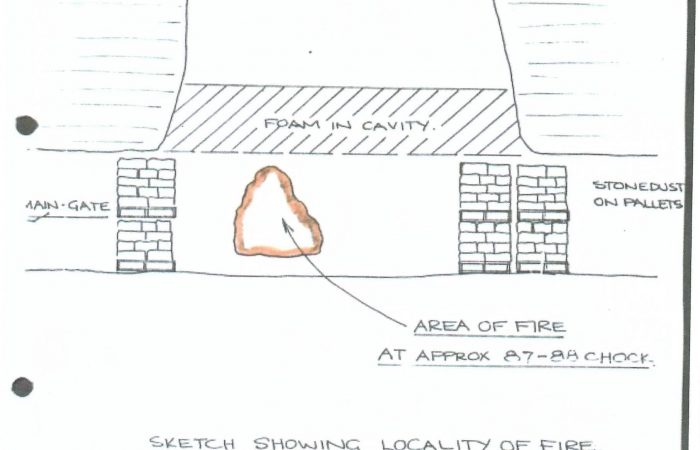

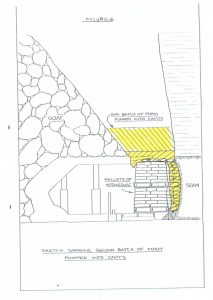

To assist, I have attached diagrams of the area provided to the investigation conducted by Ron Smith, Senior Inspector of Coal Mines

Told by Undermanager in Charge Paul Harrington that when Paul had last been in there

“He could not see the tailgate for the fumes coming off. When he left, he said it was pretty clear and you could see the tailgate quite clearly

Points to note

Arrived 8:10pm

Temperature checks by Shift Undermanager and ACIRL and Chemfix Representatives using a temperature probe.

Top of Plug 27 C at 8:30pm and 24C at 10:pm

Methane 0.2 to 0.3%

Just before 10pm whitish smoke appeared

11:30 to 11:45pm no change visible

12:45am Flames approximately 0.6 high out front of chocks.

3 fire extinguishers discharged with no visible effect.

Fire hoses used on fire in front of Chocks #87 and #88 and fire died down to virtually no flame at all and fire put out.

Hosing cavity in roof, fire on floor #87 to 88 re-ignites.

Rang Bruce Hadley Shift Undermanager at 1:25pm to inform him “we had a fire and that we seemed to have it under control”

2nd Fire Hose plan to deployed, one on cavity one on hot spot on floor #87 to #87 Chock. Pulled Stonedust bags out Stonedust Wall some found with charred material which was collected, bagged and taken out of mine later when

Mines Rescue Team led by Undermanager in Charge Paul Harrington and including Shift Undermanager Bruce Hadley arrives at the Longwall at 2:45am, assists men already there (6 including Deputy Forbes), relieves them and sends them to the surface, at which time Deputy Forbes takes the bag of charred material from the Stonedust bags out of the pit.

Bruce Hadley Shift Undermanager

First Batch PUR pumped on 12th December and non pumping period of 16 hours and fire watches commenced.

Temperature Readings in area of #86 to #87 Chock and maingate end of Stonedust

Methane 0.2 to 0.4%.

Afternoon shift 40C, Evening shift 27C and 24C “Continual Steam vapour coming off”

10:30 pm 70C and stayed steady for next 90 minutes. at midnight left the Section.

13th December

- 1:20pm Informed by Deputy Paul Forbes of the fire.

- Notified Pit Bottom Deputy Neil Campbell to take 3 miners with him to Assist Deputy Forbes and Miner Bill Morris in fighting the fire.

- All other Miners withdrawn from Mine.

- Washplant told to isolate No 1 shaft.

- 2am informed by Deputy Campbell that fire had been extinguished but there were still some hot pots in the fire area.

- After arriving as part of Mines Rescue team pulled apart the Stonedust Wall.

In process found

- Charred stonedust bags

- Burnt brattice

- Some burnt pieces of foam

- Some charred pieces of coal

- Water dripper from #88 chock quite warm cooled down approx. 5:30am

Undermanager in Charge Paul Harrington.

Dyke known to be soft running across Longwall 7 block.

Start of block dyke is 30m from the tailgate of a 150 wide face.

Call cut 40m and fall about 5 metres long occurred that buried and stalled the AFC.

A loader was used to remove the material on the AFC.

When tried to advance again more material fell where there was a 3.5 metre void between the chock tips and the coal face.

The void was up to 20metres high.

Decided to try and get mining again safely they would

- Construct an artificial roof

- Consolidate the seam and strata above the seam in the vicinity of the face

- Beam made would have to be able to withstand impact of rocks falling 20metres

- Would require large heavy steel beams to be transported down the face and erected

This idea was abandoned due to it being impossible to construct without exposing workers an extremely dangerous situation working under and in the vicinity of an unsupported fall.

The situation was sufficiently bad for the mine to seriously consider of shortening the longwall face using a continuous miner driving a heading from the maingate side.

The idea was abandoned due to the chocks not being able to be removed safely and one of more chocks would likely be lost.

Need a roof formed of light material that could erected safely and still withstand a fall from the top of the goaf.

PUR material had been used as a strata binder at the mine.

Paul Harrington

“This material is very light, however once set, becomes very strong”

11th December 3:30am to 10:am

1300 litres PUR pumped on into cavity in front of chocks #85 to 91.

Filled “the void in between the stonedust and the face and there was a thin layer across the extension bars of the chocks.

Informed 11th December 11:00 am no more that 1000 litres to be pumped or no more than 1m in depth.

Pumping should then cease for 16 hours to allow cooling.

12th December

4:00 am. A total of 1300 litres pumped pumped in 3.5 hours starting at 4:00 am and finishing at 7:30am

10:30 am phoned by distressed Warwick Anderson (presume he was the Section Deputy).

- Yellowish/brown fumes coming off PUR coming from what appeared to be a boiling mass.

- Boiling material half way across the cavity and closer to the face.

- Anderson told by Hetherington to break the stonedust hose and push stonedust up over boiling material in question

- John Schott Chemfix Representative contacted and he agreed covering with stonedust way to go.

- Harrington asked Schott for a data sheet on fumes being released and the effects of men working in the contaminated area.

- Schott told them to “Stay on the fresh air side”

ACIRL turned up late Friday afternoon as they had a lot of difficulty procuring the materials to construct a heat sensing probe.

A group consisting of Harrington, Schott, Mr Malcolm Loy (District Check Inspector) and Mr T. Carr (Local Check Inspector). Mr Loy and Carr had already inspected the Longwall face previously and returned to the Section with Harrington and Schott.

Loy informed the group definite colour change in smoke and it was less dense.

Schott said problem caused by

- Second 1300 pour was pumped too fast.

- Should have been pumped over 6 to 8 hours

- Change in colour and density clear indicator that the material was cooling down

While travelling outbye to pit bottom several stops were made to check district and main return airways.

Fumes had contaminated all these roadways back as far as No 1 Upcast shaft.

Decided to

- Isolate the 4 Area of the mine due to contamination of the 2nd Egress.

- Only leave a Deputy (Forbes) and Mines Rescue Trainee (Morris) in Area 4 on fire watch.

- Deputy and offsider told to stay on fresh air side of problem area.

- Evening Shift only worked 3 Area of the Mine.

Harrington left Westcliffe Mine at 11:05pm the 12th December.

Contacted by the Mine between 1:00am and 1:30 am told there was a fire