Grosvenor Development Floor Methane Emissions and Inrushes May 2017 to June 2019

Methane Floor Inrushes continue to occur at Grosvenor Mine during development in MG 103 and MG 104 after Inspector Browns May 2017 Directive.

In MG 104 the frequency of inrushes and the amount of Methane gas released is increasing from 101 and 102 as the panels get longer

The Grosvenor Mine have identified the zone of greatest risk in the LW 104 Second Workings SOP being inbye 20c/t

No pre drainage of the GML seam has been conducted for LW104. The GML is expected to release gas due to the reservoir size combined with proximity to the working seam between Ch4000 and Ch2000 (MG104 20-36c/t)

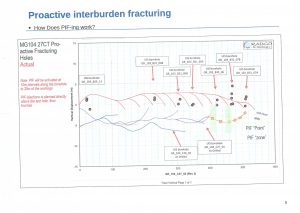

Grosvenor Management introduced a PIFF Proactive Interburden Force Fracturing Trial to attempt to deal with Methane Floor Inrushes in LW 104

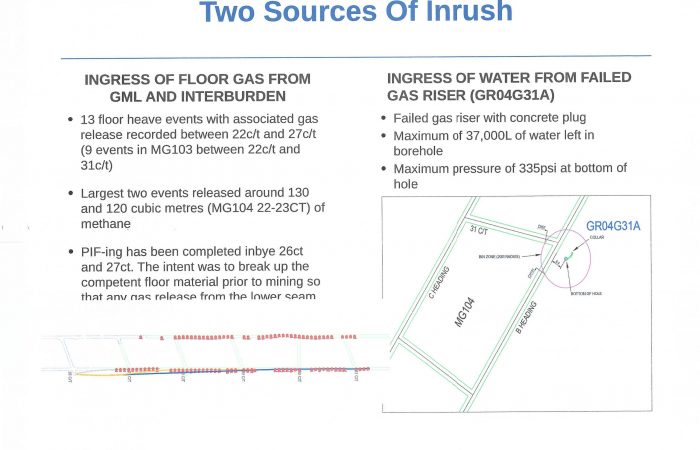

The workforce presentation on Page 2 notes there were 13 「floor heave」 methane inrushes, 9 in MG 103 and 4 in MG 104 development inbye 22 cut-through, the largest of which released between 120 and 130 m3 of methane

At last Anglo Grosvenor have acknowledged the events for what they are at this point “INRUSHES“.

As I have posted previously a number of Regulations come into place; as a minimum this includes

292 Data about potential inrushes

If underground mine workings may be affected by an inrush, the site senior executive for the mine must ensure the following matters are investigated and details of them kept at the mine—

(a) the location and nature of the inrush source;

b) the nature and thickness of the strata, measured in any plane, separating the inrush source from the workings that may be affected;

c) the presence of any faults, dykes or boreholes in the separating strata;

d) the anticipated accuracy of the details mentioned in paragraphs (a) to (c);

e) any other relevant data.

293 Risk assessment

- This section applies if there is a risk of inrush, including, for example, from cyclonic weather conditions, flood water or a breached dam, at an underground mine.

- The site senior executive for the mine must ensure a risk assessment is carried out to see whether the mine’s method of working and precautions adopted in the workings reduces the risk to acceptable levels.

- If the method, or precautions, are subsequently revised, the underground mine manager for the mine must ensure a further risk assessment is carried out.

Whether there was a formal risk assessment, which requires Mineworker Involvement was conducted is a question only Anglo Grosvenor Management can answer.

What if any communication occurred between Anglo Grosvenor and the Inspectorate about these events being Inrushes only Anglo and the Mines Inspectorate can answer

That leaves the question of “Whether the mine’s method of working and precautions adopted in the workings reduces the risk to acceptable levels”

I say from the available evidence that it did not

From the circumstances of some of the methane HPI’s, it is plain that the actual in situ gas content of the floor seams is increasing.

For example, on the 30th of January, Two auxiliary fans are ventilating the heading the continuous miner is mining in and delivering supposedly up to 30m3/s of ventilation.

Yet during the methane Inrush on that day a Hand held Gas Detector at the continuous miner recorded peak readings of 5% CH4.

The internal Methane monitors in the Auxiliary fans recorded peak readings of 2.36% and 2.97% CH4 respectively.

I have collated information from 7 of the referenced 13 Methane Inrush HPI’s in the document link directly below

FLOOR SEAM INRUSHES DEVELOPMENT

On page 5 of the PIFF Workforce Presentation there is a diagram of a PIFF drilling program.

The red line on the diagram is not something I can explain as it appears at first glance to be above the mining horizon not below it