What did the Mines Inspectorate do about Grosvenor Floor Methane Gas Emissions and Inrushes 2016 to 2020. Not Much to Nothing

With the Grosvenor Inquiry terms of reference time frames, there was little mention of events prior to July 1st 2019.

Therefore the vast majority of the methane HPI’s, the Anglo Accident Investigations (LFI’s), the Reports to the Inspectors and any associated correspondence and discussions were never mentioned at the Inquiry.

Like all such disastrous events such as the LW 104 Face Ignition there are multiple conditions/factors that must line up for the event to occur. (James Reason Swiss Chees Model)

For simplicity sake lets just keep it two, the presence of an explosive methane concentration and an ignition source.

You can have either condition/factor occur alone and there is no explosion.

However when explosive concentrations continually occur at any production face (whether development or longwall), it is almost inevitable that at some stage an ignition source and a methane flammable mixture coincide, with the inevitable result.

When trying to understand Grosvenor Mine and its oversight and compliance by the DNRME (RSHQ) Inspectors over time, it is instructive to start with some of the comments of the 11th February 2016 Structured Inspection on ventilation standards at Grosvenor Mine by Inspector Richard Gouldstone and Acting District Inspector Shaun Dobson.

11.02.2016 Vent audit MRE – Grosvenor Coal Mine –

We examined the mine plan and Mr Bobeldyk and Mr Webber explained the Mine Ventilation system.

The main features are –

- Two surface intake drifts for Men & Materials, and Coal Conveying.

- Six Mains headings(A to F), with a number of supplementary connections at the drift bottoms

- A heading is the principal return with a first balancing overcast at 1 ICT

- The Mains are driven to 20CT giving access to 101, 102 & 103 panels

- Developments currently in progress are MG & TG 101(2xCM each) plus MG 102 (IxCM)

- LW 101 Faceline is soon to be driven from 24CT

Clearly the Mine is well ventilated having only developments, no longwall and 25km of new roadways.

It was explained that after LW 101 and 102 the longer run faces will be ventilated utilising refrigeration and shafts in the gateroads.

Closing Comments

The Mine has a robust well documented system. A small sample of the system was examined with, in most cases practical evidence of effective implementation.

The Mine is relatively uncomplicated at present but it is anticipated that the future will present more challenging conditions especially in regard to working temperatures and effective pre-drainage of methane from Goonyella Middle seam and surrounding strata.

The Mines Department Inspectors after a Two Day Ventilation Audit formally acknowledge and warn that effective pre- drainage of methane will be required of both the Goonyella Middle Seam and surrounding Strata and in their terminology will present more challenging conditions.

They have also come to the opinion that the Grosvenor Mine has a “Robust well documented system.”

At least part of the Inspectors comments about pre-drainage come from two days previously, when Grosvenor Mine had informed the Inspectorate that there had been floor heave and a methane inrush event in development.

Work was in progress at MG 101 24CT C Heading, bolting the roof and both ribs when a ‘bump’ was heard by operatives. It was noticed that floor heave was occurring and witnesses reported an unusual odour. The gas monitoring devices held by ERZ Controller and a CMW began alarming. The CMW hit the Estop on the continuous miner (12CM12) dropping power to the machine.

After consideration of the initial information the decision was made by Inspector Richard Gouldstone and Acting District Inspector Shaun Dobson to travel immediately to the Mine to investigate the matter.

They note in the Mine Record Entry

In this incident, elevated methane and alleged lowered oxygen content have been experienced associated rapid floor heave in close proximity to the working face.

Rapid floor heave has been encountered in a similar fashion on previous occasions but usually further from the working face. There has been no record of associated gas level fluctuation.

A fissure in the floor extending back from the continuous miner between 100-130m chainage CT23

Conditions that were not indicative of an outburst

Discussions with a cross-section of miners confirmed that similar experiences had been encountered but not necessarily as noticeable. The details were as described by Mr Watson when first reporting the incident.

Attempts should be made to identify the frequency and magnitude of those fluctuations in future.

Inspectors Gouldstone and Dobson note

An ERZ Controller to be present with coal mine workers at all times when they are working at the face of the heading.

Arrange for all continuous miner drivers to be issued with the same type of gas detector issued to ERZ Controllers.

In future down load data from all detectors used on a shift by shift basis to obtain more accurate data on transient fluctuations in gas levels.

The Definition of Inrush in the CMSHR 2017

“inrush” means an unplanned or uncontrolled flood of liquid, gas or material that has the potential to create a hazard.

Quite clearly the events at Grosvenor on the 9th of February are a turning point in how the Inspectorate treated methane in the floor seams.

If the Inspectorate had called this event and any of the future “methane that is being released during floor heave events HPI’s” an Inrush, at least the Regulations in Division 3 Precautions against inrushes” would have taken immediate effect.

The question has to be asked what would have happened from this point of time if the Inspectorate and Anglo had of called these events for what they were?

METHANE INRUSHES

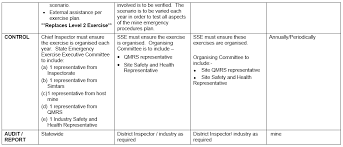

292 Data about potential inrushes

If underground mine workings may be affected by an inrush, the site senior executive for the mine must ensure the following matters are investigated and details of them kept at the mine—

(a) the location and nature of the inrush source;

b) the nature and thickness of the strata, measured in any plane, separating the inrush source from the workings that may be affected;

c) the presence of any faults, dykes or boreholes in the separating strata;

d) the anticipated accuracy of the details mentioned in paragraphs (a) to (c);

e) any other relevant data.

293 Risk assessment

- This section applies if there is a risk of inrush, including, for example, from cyclonic weather conditions, flood water or a breached dam, at an underground mine.

- The site senior executive for the mine must ensure a risk assessment is carried out to see whether the mine’s method of working and precautions adopted in the workings reduces the risk to acceptable levels.

- If the method, or precautions, are subsequently revised, the underground mine manager for the mine must ensure a further risk assessment is carried out.

The next post will be going through other MRE’s and HPI’s from Floor Methane Inrushes