GROSVENOR INQUIRY SUBMISSION. KEY ISSUE 5 Part 11. VENTSIM MODELLING and VENTILATION OFFICER VENTSIM VALIDATION FINDINGS

KEY ISSUE 5 Part 11. VENTSIM MODEL and VO VALIDATION

GROSVENOR INQUIRY SUBMISSION. KEY ISSUE 5 Part 11.

VENTSIM MODELLING and VENTILATION OFFICER VENTSIM VALIDATION FINDINGS

1) The STRATEGY to MANAGE VENTILATION in LW 104 BLOCK and RETURN was SUPPORTED by FLAWED VENTSIM MODEL that was NOT FIT TO USE in MAJOR VENTILATION CHANGE PLANNING.

2) VENTSIM MODEL WAS at GREATER THAN 15% VARIANCE and NOT FIT TO USE in MAJOR VENTILATION CHANGE PLANNING

3) FLAWED VENTSOM MODELLING was DETAILED in the SECOND WORKINGS SOP and SUBMITTED through to the DNRME

4) DIFFERENTIAL PRESSURE READINGS WERE SPARSE INDICATING THAT LITTLE TO NO VENTSIM MODEL VALIDATION DONE BY GROSVENOR VENTILATION OFFICER in 2020.

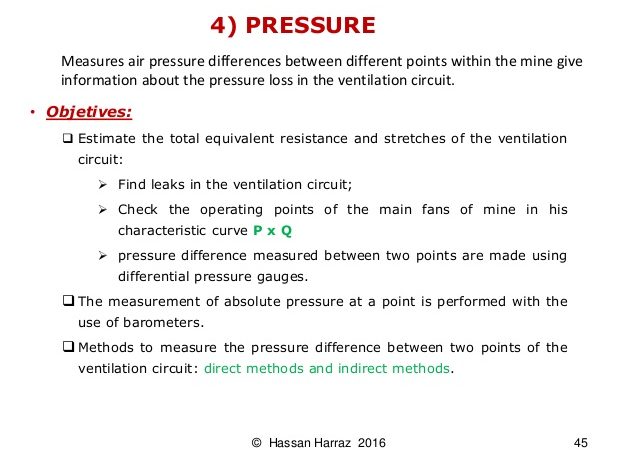

5) PRESSURE and QUANTITY SURVEYS REQUIRED for VENTSIM MODEL VALIDATION

EVIDENCE

1) NO EVIDENCE PROVIDED TO GROSVENOR INQUIRY THAT THE VENTILATION OFFICER COMPLIED WITH REGULATION 365 “MEASUREMENTS AFTER CHANGE.

365 Measurements after changes

(1) This section applies if, because an underground mine’s ventilation system is changed, air flow rates in a place mentioned in section 362(2) may be affected substantially.

(2) The ventilation officer for the mine must ensure the air flow rate for the place is measured and recorded under section 362 immediately after the change.

2) LFI IN.00224943 STATES THE MODEL SHOWS 6m3/s DROP TO LW RETURN

If there were Ventilation Measurements that confirmed the Ventilation Model, it is logical that the LFI IN.00224943 and ANGLO GROSVENOR LFI IN.00226742 & IN.00228255 (8th June Withdrawal from Mine and Ignition of Gas LW104) would state so.

3) THE MEASUREMENTS AFTER CHANGES the GROSVENOR MINE VENTILATION OFFICER WAS REQUIRED TO ENSURE, WERE EITHER

a) NOT TAKEN

b) WERE TAKEN and SHOWED SUBSTANTIAL VARIANCE TO THE MODEL

4) THE VENTILATION MODEL ANALYSIS PERFORMED BY DALLAS MINING in MAY 2019 SHOWED a SIXTY-NINE (69%) CALIBRATION VARIANCE.

ANDREW SELF REPORT

5) ANDREW SELF WOULD NOT USE A MODEL WITH MORE THAN 15% VARIANCE FOR MAJOR VENTILATION CHANGE

6) ANDREW SELF REPORT IDENTIFIES

a) 15% VARIANCE at TAILGATE MACHINE DOORS and MG 104 COFFIN SEAL and

b) 16% VARIANCE at MG104 2c/t MACHINE DOORS

c) BEFORE GOING INBYE MG 104 2c/t MACHINE DOORS VENTSIM MODEL EXCEEDS ANDREW SELF CRITERIA FOR MODELLING MAJOR VENTILATION CHANGES

d) MODEL DOES NOT INCLUDE the TWO (2) FORCING FANS at #9 SHAFT PROVIDING a POSITIVE PRESSURE of approximately 500kPa and 50m3/s of VENTILATION.

e) MODEL SHOWS #9 SHAFT as OPEN TO ATMOSPHERE

7) VENTSIM MODEL at MAY 6th 2020 DID NOT TAKE INTO ACCOUNT

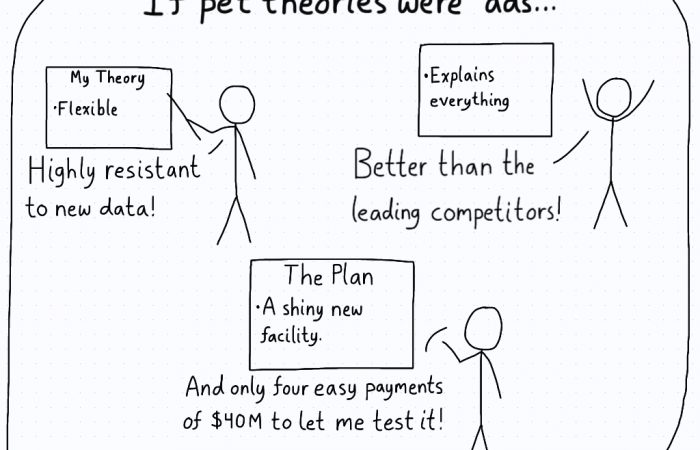

a) A learning from this investigation is that the differential pressure readings on file are sparse and there would be benefit in a more robust collation, validation and interpretation process.

b) VCDs in MG103 B-C Hdg c/t’s (inbye of 34c/t) Observed conditions differed to predictive ventsim modelling.

c) The shields at the shearer being double chocked,

d) The additional TG support (props and cogs which were erected in the TG between the PCB’s and the block side rib)

e) The TG floor heave reducing the TG roadway height to ~2.1m between the block side rib and PCB’s

f) The poly pipes layed across the TG carport to allow for ventilation in case we lost it

g) The gap between the TG carport and the underside of the canopy on #149 shield only being approximately 1.3m

h) Impact on ventilation system from goaf holes being turned on/off

ANGLO GROSVENOR in LFI IN.00226742 & IN.00228255 8th June Withdrawal from Mine and Ignition of Gas LW104