Key Issue 5. Part 5 Gas Monitoring Locations and BAG SAMPLES Details and Frequency

Key Issue 5 part 5 Gas Monitoring Location and BAG SAMPLES

DOBSON MRE – Grosvenor Coal Mine – 21.09.2016.pdf

Key Issue 5. Part 5 Gas Monitoring Locations and BAG SAMPLES Details and Frequency

Gas Monitoring Regime. Whether Sufficient Samples were being taken and whether samples were being taken at appropriate location

RECOMMENDATION

Immediate Development of a CMSHA 1999 Recognised Standard for Monitoring for Spontaneous Combustion including Key risk areas the longwall tailgate corner, pressure control around the goaf and goaf sealing.

FINDINGS

1) INTEGRITY OF GAS DATA ANALYSIS COULD BE COMPROMISED.

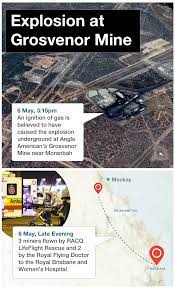

ANGLO GROSVENOR in LFI IN.00226742 & IN.00228255 8th June Withdrawal from Mine and Ignition of Gas LW104

2) GAS BAG SAMPLES WERE OFTEN NOT TAKEN IN APPROPRIATE LOCATION and WITH SUFFICIENT FREQUENCY

a) GOAF STREAM NOT INCLUDED IN TARPS

b) ISSUES with BAG SAMPLING IDENTIFIED in LFI IN.00226742 & IN.00228255 8th June Withdrawal from Mine and Ignition of Gas LW104

c) INADEQUATE FREQUENCY MG103 / TG104 B Hdg 41-42 c/t, MG103 / TG104 B Hdg 40-41 c/t, and Gas Wells GRO4V003 and GRO4V004.5

d) INADEQUATE FREQUENCY for Gas Wells GRO4V005, GRO4V005.5, GRO4V006.5 and GRO4V007 around 17 to 19th April concerning the detection of products of Spontaneous

3) RSHQ MINES INSPECTOR DOBSON in the MRE dated 21st SEPTEMBER 2016 (Attachment 1) identified.

a) The weekly bag sampling record had a large number of bag samples not recorded as being taken on the given dates.

b) The failure to complete all sections of the weekly check sheet for bag samples was also discussed where 38 of these samples had not been recorded as being taken.

4) INSPECTOR DOBSON DOES NOT RECORD ANY ACTION TAKEN TO ADDRESS THIS EITHER BY THE INSPECORATE or MANAGEMENT EXCEPT DISCUSSING it with SSE Wayne Bull, UMM Richard Livingstone Blevins, Production Manager Tim Reeves, and Technical Services Superintendent Malcolm Smyth

5) MAJOR ISSUES WITH BAG SAMPLING in 2020 as Identified in ANGLO GROSVENOR LFI IN.00226742 & IN.00228255 8th June Withdrawal from Mine and Ignition of Gas LW104

a) There are some minor inconsistencies in the naming of sample locations.

b) In the lead up to 2nd June, that there was not a consistent understanding regarding the location to take bag samples / temperatures where no clear sampling point had been established.

c) Thirdly, the use of different measuring equipment for temperature readings was noted during the investigation.

d) All three of these factors can impact the integrity of data analysis.

e) The following recommendations are provided to address this matter:

I) UG Tablets should be configured to mandate additional minimum fields for naming of sample sites (e.g. whether sample is in the MG or TG)

II) The Spontaneous Combustion TARP should include an action for the ERZ Controller to immediately demarcate sampling locations determined by the IMT

III) All ERZ Controllers should be familiarised with the preferred temperature monitoring device and the Spontaneous Combustion TARP should mandate that the same device is used across shifts

LFI IN.00226742 & IN.00228255 8th June Withdrawal from Mine and Ignition of Gas

LW104

6) 2016 “DISCUSSIONS” WITHOUT LAWFUL COMPLIANCE ACTION BETWEEN INSPECTOR DOBSON and SSE Wayne Bull, UMM Richard Livingstone Blevins, Production Manager Tim Reeves, and Technical Services Superintendent Malcolm Smyth, DOES NOT FIX MANY OF DEFICIENCIES

Most of ISSUES are STILL IDENTIFIED as EXISTING by ANGLO GROSVENOR in LFI IN.00226742 & IN.00228255 8th June Withdrawal from Mine and Ignition of Gas LW104

‘All three of these factors can impact the integrity of data analysis.’