Secondary Extraction Plans Notices and Approval. Moura No 4 Windridge Inquiry Panel Design Recommendations and Inspectors Approval Changed

In several posts I have mentioned the Second Workings Standard Operating Plans and how they are required to be submitted by notice to the Mines Inspector prior to Second Working Commencing.

This both for North Goonyella and Grosvenor.

Before I discuss the importance of the Secondary Workings/Extraction plans at Grosvenor in my next post, the history of them needs to be explained.

Mining Warden Frank Windridge made the following recommendation about Part 60 Second Workings as part of the Moura No 2 Disaster Report

Part 60 of the General Rules for Underground Coal Mines (Second Working Extraction) requires the mine manager to submit to the inspector, for approval, full details of the proposed scheme of work for the extraction of pillars or of secondary workings of bottom coal.

It is recommended, therefore, that it be made a requirement of Part 60 (Second Working Extraction) submissions that spontaneous combustion be specifically included as a factor to be considered and evaluated

Part 60 and the Training Rules were introduced after the Moura No 2 Disaster.

(Unfortunately I no longer have printed paper copies from the time, and I have been unable to locate them on the internet)

As stated in Warden Windridge’s Moura No 2 Report Part 60 of the General Rules for Underground Coal Mines (Second Working Extraction) requires the mine manager to submit to the inspector, for approval.

This approval was supplied in writing from the Inspector to the Mine.

There are a very limited number of approvals or written acknowledgements required from the Inspectors and Chief Inspector of Coal Mines under the CMSHA 1999 and CMSHR 2001. For example Sealing Underground Mine or a part of the Mine. This also includes requiring no persons underground while the newly sealed part of the mine goes through the explosive range.

Division 5 Routine and emergency sealing

S 330 Evacuating mine after sealing

A person must not, without an inspector’s written consent, enter or remain in an underground mine after the mine, or part of the mine, has been sealed.

S 327. Sealing underground mine

- The underground mine manager for an underground mine must ensure the mine, or part of the mine, is not sealed unless—

a) the underground mine manager has given notice of the proposed sealing under section 326; and

b) the inspector to whom the notice was given has given the underground mine manager a written acknowledgement that the inspector is satisfied with the details of the proposed sealing given in the notice.

2) The underground mine manager must ensure the mine, or part, is sealed in the way acknowledged by the inspector.

3) This section does not apply to sealing the mine in an emergency.

The Mines Department and Chief Inspector of the time were very firmly opposed to the giving of Approvals at all.

The only reason the Department and Inspectors agreed to keep approval for persons to remain underground after sealing part of the Mine was that after the events at Moura No 2, it was politically and practically impossible for them to oppose it in Public.

However, when it came to requirements to approve Second Works Plans and Procedures; The Chief Inspector and Department flatly refused to carry the Approval over into the new Regulations and in particular S 320 of the 2001 Regulations.

This was one of Mining Warden Windridge’s recommendations that was not accepted in full by the Government

As ISHR’s at the time, Greg Dalliston and I had major concerns and this issue was debated at length.

We had several discussions with Brian Lyne (then CIOCM), other Senior Inspectors and Mines Department Officers and correspondence was sent between the parties, as well I believe it being discussed at the Advisory Council. (I no longer have access to the correspondence and relevant information, but would be in the CFMEU Mining and Energy archives).

What was the major concern for the Department and the Inspectors?

Being held as contributing or liable along with the Mine Management if more Coal Mines had methane explosions when doing second workings.

From what we have seen and heard from the limited testimony of Mines Inspectors at the Grosvenor Inquiry about their oversight, it seems that the Inspectors and Departments concerns are justified.

Given the legal action against Peabody Energy for misleading the US Stock Market it is likely a plus for the Queensland Taxpayers as well.

Otherwise the Mines Department (RSHQ) would likely be part of the action alongside Peabody Energy with damages being sought

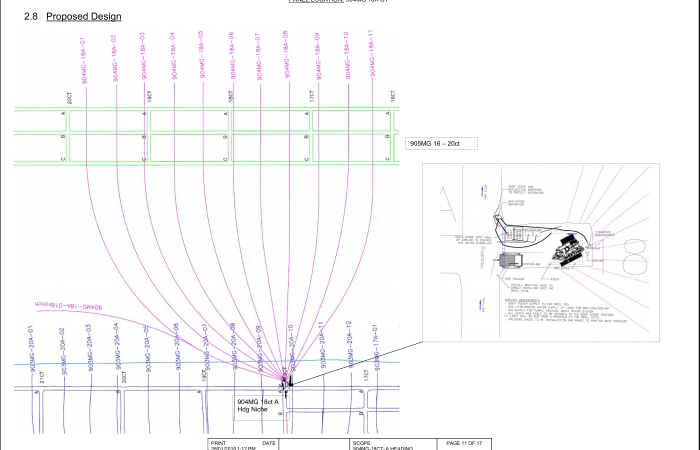

This post relates to Second Workings SOP’s and Risk Assessments for North Goonyella 9 Nth Longwall Panel in 2016.

It may give you some sense of the documentation supplied and communication between the Mine Management and the Inspectors in providing notice prior to commencing second workings

These comments are from the start of North Goon 9-Nth-2nd-workings-Audit-PB-sept-2016 (3)

On 12 September 2016, I received copies of the Standard Operating Procedure Second Workings NC-MIN-SOP-LW318, and the underpinning Workplace Risk Assessment NG-MlN-RSK-LW014 LW9N Secondary Workings, from North Goonyella Mine representative Mr Marek Romanski (UMM).

I have read and considered the documents and make the following observations on which I require a response.

Panel Design (page 63)

Part 60 of the General Rules for Underground Coal Mines (Second Working Extraction) requires the mine manager to submit to the inspector, for approval, full details of the proposed scheme of work for the extraction of pillars or of secondary workings of bottom coal.

The legislation stipulates the submission to include information on a list of factors all of which clearly relate to the safety of the proposed scheme of work. None of these factors, however, refer specifically to or can be construed as being directly related to spontaneous combustion as an issue for consideration in the proposed scheme of work.

The requirements, as set out, were complied with at Moura No 2 in respect of 512 Panel. In addition, the manager, albeit prompted by others, arranged for a risk assessment of the proposed extraction design.

The assessment made scant reference to spontaneous combustion and then only with a low level probability that it could arise from the extraction of bottom coal.

Moreover, the consequence of an occurrence was rated at the lowest safety level, mentioning short panel life and use of continuous gas monitoring as existing safeguards. Flooding the panel with water was mentioned as a further safeguard if required.

As we now know, the factors considered and taken account of in the design of 512 Panel and its extraction were lamentably inadequate.

It is recommended, therefore, that it be made a requirement of Part 60 (Second Working Extraction) submissions that spontaneous combustion be specifically included as a factor to be considered and evaluated

320 Notices to inspector

- Before second workings are started at an underground mine, the site senior executive for the mine must give an inspector notice about the proposed second workings.

2. Before the mine’s standard operating procedure for second workings is significantly changed, the site senior executive must give an inspector a copy of—

a) the report on the risk assessment carried out under section 319(3)(a) for the change; and

b) the proposed standard operating procedure.

3. Despite subsection (2), the site senior executive may change the standard operating procedure before giving an inspector the documents mentioned in the subsection if—

a) the procedure needs to be changed immediately because of prevailing mining conditions; and

b) immediately after the change is made, the underground mine manager for the mine notifies an inspector about the circumstances and details of the change; and

c) as soon as practicable after the change is made, the site senior executive gives an inspector the documents mentioned in the subsection.

4. In this section— significant change, for a standard operating procedure for second workings, means a change that is likely to significantly affect the ventilation, stability, subsidence or extraction sequence of the workings.