North Goonyella Mine Fire 16th October 2018. “Les Marlborough noted the contaminants at 10N corridor 6ct were similar to H9, 32ct G and 36ct readings other than Ethylene which appeared to be higher than the other noted locations, Darren Brady concurred.”

MRE – North Goonyella – 16.10.2018.pdf

On Tuesday 16 October 2018 Inspector Geoff Nugent attend the North Goonyella Mine

Accommodation Village to attend a meeting in regard to progress on dealing with the spontaneous combustion event arriving at 7:30am.

Update Meeting at 8:30am Tuesday 16 October 2018

Attendees —

Mike Carter (SSE Millennium Mine), Neville Impson (Compliance Manager),

Geoff Nugent (Mines Inspector), Joshua Cook (Graduate Mining Engineer and scribe) Dennis Black (Ventilation officer)

Dial in —John Anger (SSE), David Cliff (Consultant), Darren Brady (Consultant), Michael Brady

(Consultant), Steven Woods (ISHR), Martin Watkinson (SIMTARS), Shaun Dobson (Deputy Chief Inspector), Les Marlobourgh (Regional Inspector), Kevin Poynter (Regional Inspector), Richard Gouldstone (Mines Inspector) Charlie Lilly (Director of engineering Peabody USA)

Last 24hrs

Gag running & OK- end of day shift Barometer 978.3 & Rising, Back Pressure gag 1.85 kPa, Borehole

Pressure -88 Pa, Turbine Temp 562Degees C , 02 4.1%, CO 260ppm, C02 11.4%

At the end of night shift GAG 5% 02, 185ppm CO, 11.6% C02, Back pressure 2250pa, Borehole 85pa”

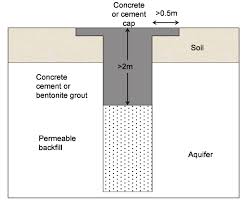

Current borehole status; o GN2705 – MG Chute MID- DR1265-Cased and grouted, waiting on concrete to set for drilling o GN2709 – TG Chute MID- DR1226-Completed and moved to GN2710 TG chute outbye drilled 6m cased and grouted e GN2708 -MG Chute outbye- DR1218- Reamed and removing rods running casing

Drilling pad prep status; o GN2706 pad is prepped and ready to go

- GN2707 pad is prepped and ready to go GN2711 pad is prepped and ready to go e GN2712 pad is prepped and ready to go

- GN 2710 – pad is prepped and ready to go

- GN2714 awaiting 1M T decision on location of borehole ( inbye or outbye of 2704)

GN2713 ground truthed location, waiting to see if hole will be needed (depending upon 2705 success)

Borehole gas monitoring 6 hrly all samples

Carting material to H9 for contingency sealing

Heat temp reading at H9 – 27-33% at 07:20hrs

Ran tube bundle from tube bundle hut (TBH) to drill site, extended F8 to TBH, 8ctC-D coupled to TB34

TBH, 9NMG 10.5 (428m) and 25 (404m) dropped down risers, 6 x TB connected to Simtars LAB

Floxal #2 down 00:10 to 01:45 while tubes run to 6ct corridor

Camera images collected from GN2704 and GN2709

Batch plant assembled, commissioning ongoing

Gas Drainage measurements #9 at 46.5c/t = 911/sec flow; #3 at 44c/t zero flow. #8 at 52c/t has zero flow & is isolated. #4 at 2c/t 10Sth = 3931/sec flow. #7 at 4c/t 10Sth has zero flow. SIS #1 480/sec flow & SIS#2 has flow but the screen no longer works; UIS 2c/t 4281/sec flow. 46.5 781/sec flow,

RADON Survey 140 holes C and D grid with cups, 34 cups removed for testing from eastern end of C grid

3N 1ct, G32, 36ct D-E, E44 completed and connected to TBH, Run Tube down GN1754 and to TBH, 10 tubes run from TBH to Simtars LAB require joiners ETA site 10:00hrs, Split tube repaired 32ct, connected GN2704, ION 6ct, 9N 5ct, 9N 10.5ct, 9N 25ct connected to TBH Moved Floxal #1 to 1-2ct 9N

Next 24

Continue GAG operations (planned to shut down on NS for maintenance)

Continue drilling for LW containment

Continue sampling regime and setting up tubes at sample points

Camera down GN2705

Liquid cement Batch Plant assembly

Liquid N2 and Floxal #1 set-up 1-2B 9N

Carting coarse reject to H9 for contingency sealing

Ducting delivery and prep for install H40 GAG connection

Rocsil plug NS GN2708 MG chute outbye plug DR1265 relocate to GN2706 2ct MG 0B hole

Meeting Notes

NGC borehole Gopro camera took video in Borehole GN2704 Tailgate roadway. Images observed indicated no signs of combustion in this area, newly installed tube bundle line on roof in good clean condition, brattice wing standing and no signs of combustion impact or products of combustion, additionally hanging stonedust bags showed no impact from combustion or over pressure event. NGC 1MT determined that GN2704 entered the roadway on the Goaf side of the double seal skins due to TB line on roof and presence of brattice wing.

Video footage from GN2709 in TG chute, outbye of Rocsil plug, was limited to a couple of frames of the roof mesh and roof due to complications with the camera arrangement. The images of the roof and mesh observed showed no signs of combustion impact. A temperature strip was also sent into the roadway at GN2709 and indicated approx. 400c

Cited that H9 shaft raw CO had been steadily increasing, Darren Brady noted that the airfree CO at H9 has been stable.

Les Marlborough noted the contaminants at 10N corridor 6ct were similar to H9, 32ct G and 36ct readings other than Ethylene which appeared to be higher than the other noted locations, Darren Brady concurred.

Darren Brady noted that CO (although minimal 34ppm) has been detected for the first time at 44ct E, sample taken 0325hrs 16.10.2018. Dennis Black indicated the tube end was toward the top of the borehole.

Mike Carter stated that NGC were developing a gas monitoring spreadsheet to better track location and status of monitoring points e.g end of TB location in bore hole or in seam, additionally NGC procuring thermo couple temperature probes to install with gas monitoring.

NGC continuing to establish tube bundle lines back to NGC tube bundle hut for continuous monitoring.

Les Marlborough suggested taking bag samples from locations where concrete will be dropped underground for Longwall seals to determine if an explosive mixture exists. Mike Carter explained that the concrete will be delivered underground through the drill rods and will be a very wet mix.