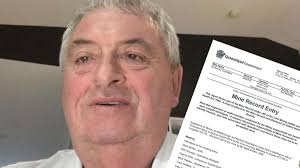

North Goonyella Mine Fire 22nd September 2018. “Starting to see increase of CO at TB14 MG Chute (CO 49.6ppm 0800hrs) and TB38 E frame goaf side (CO 17 ppm 0800hrs).”

MRE – North Goonyella – 22.09.2018.pdf

These are the most relevant sections of the Mine Record Entry

Please note multiple Risk Assessment for Re-Entry and Sealing Activities and Longwall Recovery.

Also note

Shutting off of the Bleeder Fan

Starting to see increase of CO at TB14 MG Chute (CO 49.6ppm 0800hrs) and TB38 E frame goaf side (CO 17 ppm 0800hrs).

Have not seen any major impact to gas composition since turning Bleeder fan off

RA – review Wilsons remote sealing, identified identical hazards and will require re-ranking using Peabody matrix

RE-ENTRY PLAN : RA- chute road sealing (to allow underground entry to extract LW9N supports)

Shut off bleeder fan at 1 1:30am

RE-ENTRY PLAN : Identified location of 2nd borehole for tube bundle monitoring point in TG

Chute road and completed site preparation

Meetinq Notes

Acknowledge injection of gas @ GN1991 is preventing the gas in the goaf presenting to TB24 impacting effective monitoring at the TG seal. Expected products of combustion reporting to TB29 and TB28

Wilsons and drillers will conduct trial run of implementing process for plan B at a Borehole in south mains area.

Tuesday 25/9/18 N2 units to have maintenance conducted sequentially

Plan for re-entry and Plan B will be delivered to DNRME 23/9/18 with list of associated RA Requested that plan and associated RA presented to Inspectors Keith Brennan and Geoff Nugent 22/2/2018.

John Anger (SSE) provided both draft power point presentation for re-entry plan and draft re-entry Risk Assessment

RA for application of Rocsil and sealing TG chute road SSE to confirm it was conducted with NGC Personal under NGC SHMS and RM process,

Gas Review

Barometric pressure abnormally high and expecting high pressure over next 3 days

TB29 gas levels remain stable, CO trending with Diurnal

TB28 Stable

Starting to see increase of CO at TB14 MG Chute (CO 49.6ppm 0800hrs) and TB38 E frame goaf side (CO 17 ppm 0800hrs).

Have not seen any major impact to gas composition since turning Bleeder fan off

Today the 21st September 2018 Department of Natural Resources Mines and Energy Deputy

Chief Inspector Shaun Dobson and Inspectors Geoff Nugent and Keith Brennan travelled to North Goonyella underground operations to continue monitoring the mine’s progress in managing a spontaneous combustion event occurring on Longwall 9 North recovery faceline. An Incident Management Team meeting was convened for 8:30am and was attended by the following.

- North Goonyella SSE John Anger

- Technical Services Manager Steven Stook

- Site Safety and Health Representative Peter Purdie

- Ventilation Officer Dennis Black

- Development Coordinator John Martin

- Dial in — Peabody Operations Manager Peter Baker, Deputy Chief Inspector Shaun Dobson, Consultants Michael Brady, Darren Brady, Compliance Manager Neville Impson UMM Marek Romanski, SIMTARS Martin Watkinson

Last 24

Drilling GN2697 (TG Chute road) to target depth, reaming out due to hole stability issues casing grouted and wait, then completed hole through (366m) 2230hrs 21/9/18

Drilling GN2698 (Between GN2693 and GN2470) – hole progressed to casing depth at 224m slow penetration rate due to fracturing, cased and pressure grouted

2698 crew put on 2699 until grout cured in 2698 3rd Narrabri unit ETA on site Tuesday next week

QMRS Foam assist with GN2697 hole through

Floxal 6 flow reduction found to be due to compressor issues – getting new compressors delivered by Tuesday next week

Liquid N2 increased average rate of 348 1/s

Overall increase of 180 l/s

Liquid N2 increased from 157 l/s to 348 l/s average

Floxal 6 re-tasked to GN1991 from GN2690

RA – review Wilsons remote sealing, identified identical hazards and will require re-ranking using Peabody matrix

RE-ENTRY PLAN : RA- chute road sealing (to allow underground entry to extract LW9N supports)

Shut off bleeder fan at 1 1:30am

RE-ENTRY PLAN : Identified location of 2nd borehole for tube bundle monitoring point in TG

Chute road and completed site preparation

Next 24

Sourcing tube bundle to run from TB hut to GN2700

Source additional supply of Floxal to be used in other holes than can come on line

Continue DS drilling GN2699 – install casing

Continue drilling GN2698 to completion and install slider casing to depth

Drilling GN2700

Take Bag samples shiftly from TB#14 (Maingate Chute Roadway) and TB#38 (E Frame, Goaf side of Frame)

Test run on the surface, running hoses and clamping around rods for GN2697 to understand timing of activity to sync in with completion of GN2700 hole through and tube bundle installation.

RE-ENTRY PLAN : stress test the chute road sealing, RA

Re-calibrate the tube bundle

Prepare tube bundle route, includes using Vacuum truck to excavate out from underneath 2 cattle grids

Floxal Strategy

Tuesday 25th September – Floxal maintenance planned

Identify compatibility of Millennium Floxal compressors with Narrabri AFTECH unit (Floxal 6)

Meetinq Notes

Acknowledge injection of gas @ GN1991 is preventing the gas in the goaf presenting to TB24 impacting effective monitoring at the TG seal. Expected products of combustion reporting to TB29 and TB28

Wilsons and drillers will conduct trial run of implementing process for plan B at a Borehole in south mains area.

Tuesday 25/9/18 N2 units to have maintenance conducted sequentially

Plan for re-entry and Plan B will be delivered to DNRME 23/9/18 with list of associated RA Requested that plan and associated RA presented to Inspectors Keith Brennan and Geoff Nugent 22/2/2018.

John Anger (SSE) provided both draft power point presentation for re-entry plan and draft re-entry Risk Assessment

RA for application of Rocsil and sealing TG chute road SSE to confirm it was conducted with NGC Personal under NGC SHMS and RM process,

Gas Review

Barometric pressure abnormally high and expecting high pressure over next 3 days

TB29 gas levels remain stable, CO trending with Diurnal

TB28 Stable

Starting to see increase of CO at TB14 MG Chute (CO 49.6ppm 0800hrs) and TB38 E frame goaf side (CO 17 ppm 0800hrs).

Have not seen any major impact to gas composition since turning Bleeder fan off

N2 foam used to hole through into TG Chute (100m3), could impact TB29 from sucking foam. Additionally Foam may increase resistance in TG Chute contributing to CO presenting to TB14 &TB38 including PD change from turning bleeder fan off.

Darren Brady recommended a person to physically monitor TB29 in TB so analyser is not impacted by foam.

N2 injecting at 1991 (4431/s) may not be effective and following air path around TG to TG chute and not influencing generation of CO. NGC are considering moving N2 volume to another location and apply lower volume at GN1991 i

Current total volume of N2 being applied 2.1 m3/s