North Goonyella Mine Fire 21st September 2018. “Discussed validity and applicability of TARPS being applied for any proposed re-entry, must have clearly defined conditions and parameters to demonstrate no ignition source exists and must contain explosibility risk.”

MRE – North Goonyella – 21.09.2018.pdf

I have cut out and highlighted the most important parts of the Mine Record Entry

Meeting Notes

NGC have conducted RA to turn Bleeder fan off provided explanation of impact of proposed change via ventsim.

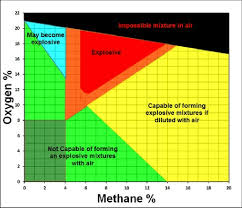

Issue raised with accumulation of CH4 in 9N B heading at 8m3/s and bleeder heading, no RT monitoring in B heading due to power turned off from ION due to flooding, TB37 9N 24-25ct currently 0.08% CH4

No other monitoring in 9N bleeder or ION install and Bleeder. 4 Way monitor operating ION MG inbye A heading coffin seal CH4 increased from 0.5% to 0.76% after Bleeder fan turned off

Raised view that Plan B sealing appears to be priority over Plan A inertisation, assured Plan A is priority but operating in parallel

Discussed validity and applicability of TARPS being applied for any proposed re-entry, must have clearly defined conditions and parameters to demonstrate no ignition source exists and must contain explosibility risk.

Additionally once yet to be defined conditions are met, demonstrating stability of the environment over a defined time prior to re-entry must be identified.

Darren Brady commented on the surprise increase of CO at TB24 after CH4 turned off at GN 1991. After Floxal applied at GN 1991 CO starting to roll over.

Injecting at GN 1991 could be masking what is being produced.

Strategy still to target TG area with all inert gas to squeeze product towards TG chute

NGC does not feel they will get value from tracer gas, also needs to be imported from overseas, SIMTARS does not analyse tracer gas anymore.

Still need to determine all impacts on whole of mine if TG chute is sealed, Dennis Black analysing.

Stated that it is difficult to identify what changes have impacted results and require status quo for a period after change to determine effects

RA review Wilsons remote sealing, identified identical hazards and will require re-ranking using Peabody matrix

Floxal 4 incident investigation completed

RA – to shut off bleeder fan

RE-ENTRY PLAN : RA – chute road sealing, brain storming before preparing WRAC ahead of

RE-ENTRY PLAN : Identify location of 2nd borehole for tube bundle monitoring point in TG Chute road to assist with environment monitoring post and pre-sealing

Next 24

Investigate additional supply of Liquid N2 to increase delivery rate

Review RA – to shut off bleeder fan

Pending feedback, modify bleeder fan shut off RA and implement pending review of tube bundle monitoring data – off at 1 1:30am

RE-ENTRY PLAN : RA – chute road sealing, preparing WRAC ahead of RA – include Ethylene trigger and discuss with DNRM / SIMTARS

RE-ENTRY PLAN : Identify location of 2nd borehole for tube bundle monitoring point in TG

Chute road to assist with environment monitoring post and pre-sealing

RA – review Wilsons operational RA for remote Rocksil seal installation after modification for additional controls

Re-introduce additional inertisation capacity into GNI 991 due to immediate adverse effects in Tube #24 as a consequence of turning off CH4 to GNI 991

Today the 22nd September 2018 Department of Natural Resources Mines and Energy Inspectors Geoff Nugent and Keith Brennan travelled to North Goonyella underground operations to continue monitoring the mine’s progress in managing a spontaneous combustion event occurring on Longwall 9 North recovery faceline. An Incident Management Team meeting was convened for 8:30am and was attended by the following.

- Peabody Operations Manager Peter Baker

- North Goonyella SSE John Anger

- Underground Mine Manager Marek Romanski

- Technical Services Manager Steven Stook

- Industry Safety and Health Representative Steven Woods

- Site Safety and Health Representative Peter Purdie

- Safety Health and Environment Manager Gavin Shields

- Senior Geologist Arthur Dybowicz

- Ventilation Officer Dennis Black

- Development Coordinator John Martin

- Development Coordinator Lee Earnshaw

- Dial in Technical Consultants:- Darren Brady, Martin Watkinson and Compliance Manager Nev Impson

Last 24

Drilling GN2697 (TG Chute road) to target depth, reaming out due to hole stability issues casing run in

Drilling GN2698 (Between GN2693 and GN2470) hole progressed to casing depth at 224m slow penetration rate due to fracturing 3rd Narrabri unit ETA on site Tuesday next week

QMRS Foam setting up to assist GN2697 hole through

Ran water into GN2696 and hole took water but closed up afterwards, suspect that swelling clays are closing in on hole similar to a neighbouring mine

Floxal 6 flow reduction found to be due to compressor issues – getting new compressors delivered by Tuesday next week

Liquid N2 installed on GN2693

Liquid N2 reduced to 157 IIS to ensure that continuous feed is maintained

Floxal 2 and 4 re-established on GN2695

Floxal 6 re-tasked to GN2690

RA review Wilsons remote sealing, identified identical hazards and will require re-ranking using Peabody matrix

Floxal 4 incident investigation completed

RA – to shut off bleeder fan

RE-ENTRY PLAN : RA – chute road sealing, brain storming before preparing WRAC ahead of

RE-ENTRY PLAN : Identify location of 2nd borehole for tube bundle monitoring point in TG

Chute road to assist with environment monitoring post and pre-sealing

Shut off CH4 injection into GN1991 1400hrs 20/9/18 placed unit 6 Narrabri unit at 3461/s

Next 24

Investigate additional supply of Liquid N2 to increase delivery rate

Review RA – to shut off bleeder fan

Pending feedback, modify bleeder fan shut off RA and implement pending review of tube bundle monitoring data – off at 1 1:30am

Complete GN2697 hole through

GN2698 – grout casing and allow to cure – having issues with getting circulation back to surface. We need to establish this prior to back grouting

GN2698 – pending grout and curing of casing, punch through cement shoe and drill to target depth

Continue DS drilling GN2699

RE-ENTRY PLAN : RA – chute road sealing, preparing WRAC ahead of RA – include Ethylene trigger and discuss with DNRM / SIMTARS

RE-ENTRY PLAN : Identify location of 2nd borehole for tube bundle monitoring point in TG

Chute road to assist with environment monitoring post and pre-sealing

RA – review Wilsons operational RA for remote Rocksil seal installation after modification for additional controls

Re-introduce additional inertisation capacity into GNI 991 due to immediate adverse effects in Tube #24 as a consequence of turning off CH4 to GNI 991

Temporarily assign Floxal 4 on to ONI 991 – (can be immediately turned on via valve), once Floxal 6 can be connected, re-assign Floxal 4 to GN2695

Source additional supply of Floxal to be used in other holes than can come on line – this new source can be used to pressurise GN2696 in order to encourage flow

Contact Narrabri CIMM to see if it can release the liquid N2 on their site that is no longer required for use

Floxal Strategy

Floxal 6 ( Narrabri unit ) from GN2690 to GN1991 – completed at 8:45am

Once GN2698 is completed, take a bag sample, describe condition of gas purging out of the hole and relocate liquid Nitrogen to there – set up reticulation

Meeting Notes

NGC have conducted RA to turn Bleeder fan off provided explanation of impact of proposed change via ventsim.

Issue raised with accumulation of CH4 in 9N B heading at 8m3/s and bleeder heading, no RT monitoring in B heading due to power turned off from ION due to flooding, TB37 9N 24-25ct currently 0.08% CH4

No other monitoring in 9N bleeder or ION install and Bleeder. 4 Way monitor operating ION MG inbye A heading coffin seal CH4 increased from 0.5% to 0.76% after Bleeder fan turned off

Raised view that Plan B sealing appears to be priority over Plan A inertisation, assured Plan A is priority but operating in parallel

Discussed validity and applicability of TARPS being applied for any proposed re-entry, must have clearly defined conditions and parameters to demonstrate no ignition source exists and must contain explosibility risk.

Additionally once yet to be defined conditions are meet, demonstrating stability of the environment over a defined time prior to re-entry must be identified.

Darren Brady commented on the surprise increase of CO at TB24 after CH4 turned off at GN 1991. After Floxal applied at GN 1991 CO starting to roll over.

Injecting at GN 1991 could be masking what is being produced.

Strategy still to target TG area with all inert gas to squeeze product towards TG chute

NGC does not feel they will get value from tracer gas, also needs to be imported from overseas, SIMTARS does not analyse tracer gas anymore.

Still need to determine all impacts on whole of mine if TG chute is sealed, Dennis Black analysing.

Stated that it is difficult to identify what changes have impacted results and require status quo for a period after change to determine effects