Marlborough 168 Directive extended 13th OCTOBER 2017

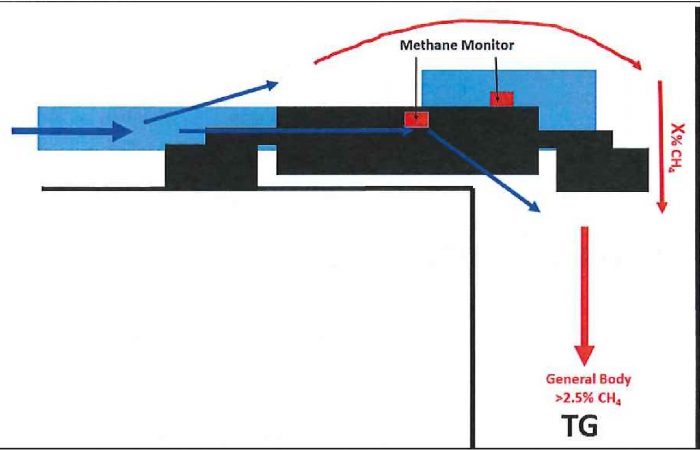

The sketch below shows a typical layout when the LW Shearer is in the TG end of the Longwall. The Methane monitor on the TG Drive, is typically positioned above the TG AFC motor and is 3-5 m from the end of the AFC. The shearer Methane monitor is typically situated in the middle of the shearer on the goaf side of the shearer.

As can be seen from the sketch, when there is a situation with greater than 2,5% Methane in the TG general body, the Methane reading on the TG AFC and Shearer monitors are typically 0.5% or less. This means that the bulk of the Methane reporting to the Tailgate Roadway is being swept out from the goaf fringe by the air stream that is deflected round the shearer as it travels into the TG end. It will be highly likely that this Methane rich air stream will be in excess of

5% Methane and will flow over the TG shearer drum, which normally has to cut approximately

1.5 m beyond the end of the TG AFC Drive to trim the floor to allow the drive to be advanced.

Typical LW TG Arrangement Sketch

The most recent ignition event on a Longwall in Queensland occurred at the TG end of the AFC and the ignition source was believed to be from the TG AFC Sprocket area. The shearer was positioned in the TG at the time of the ignition. The AFC was running, the shearer was powered, but the cutter drums were not engaged at the time of the ignition.

The TARP and the explanatory letter provided by the mine, stipulate that power will instantaneously be tripped to the shearer when the TG GB Methane at the Methane Monitor located 400m outbye of the face reaches, or exceeds 2.5%.

The TARP then states that the shearer may be moved clear of the TG shuffle zone with the authorisation of the Underground Mine Manager. It goes on to explain that deteriorated roof conditions or moving the shearer to reduce Impact on goaf gas fringe may be reasons for wanting to move the shearer. The data supplied by the mine in response to the MRE does not demonstrate that the shearer standing in the TG shuffle zone increases the methane being swept out into the TG-

The letter from the Chief Inspector of Coal Mines sent to all Coal Underground SSE’s and Underground Mine Managers on 30 Jan 2017 clearly states that if a roadway in a mine contains an atmosphere equal to or greater than 2.5% methane it is dangerous under section 273 of the Act. The letter also goes on to state that the SHMS must have controls to prevent a general body concentration of methane occurring in any roadway that is equal to or greater than 2.5%.

For the above reasons it is not considered an acceptable level of risk to move the shearer whenever the methane level in the TG general body is at or greater than 2.5% and so the requirements of the Directive are not satisfied.

I will extend the Directive completion date to Friday 27 October 2017 in order to allow the mine to respond to this MRE.